Lincoln Corsair: Engine System - General Information / General Procedures - Powertrain/Drivetrain Mount Neutralizing

Adjustment

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

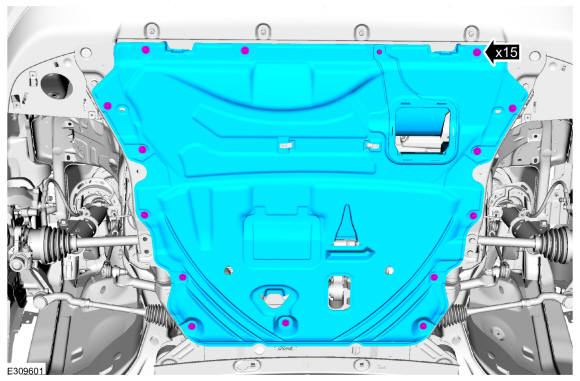

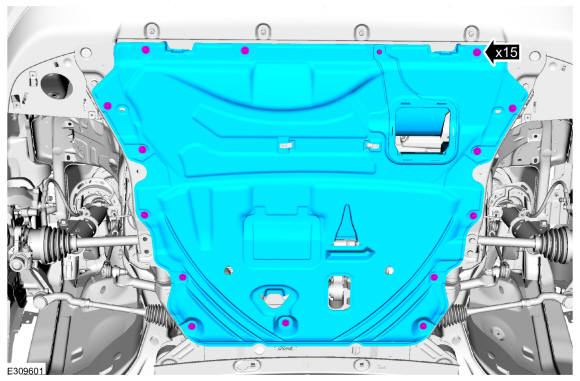

Remove the fasteners and the undershield.

-

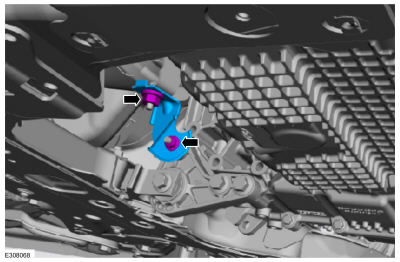

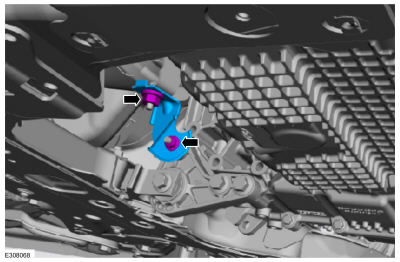

Remove the nuts and the bracket.

-

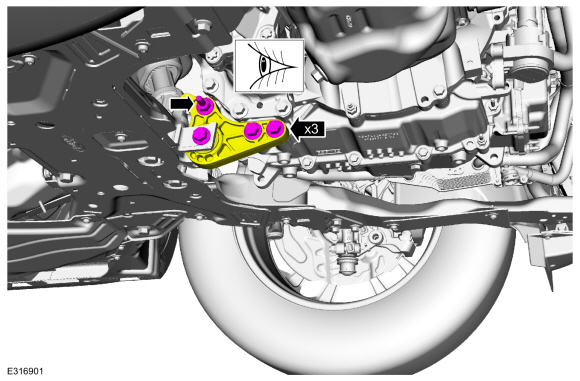

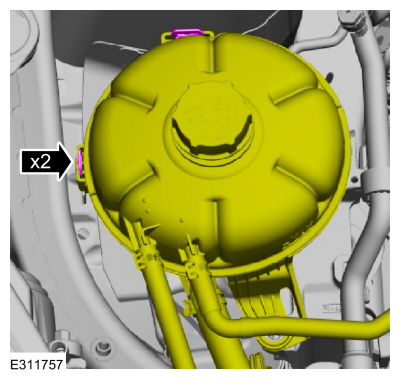

Loosen, but do not remove the roll restrictor fasteners. Verify that the roll restrictor is loose.

-

-

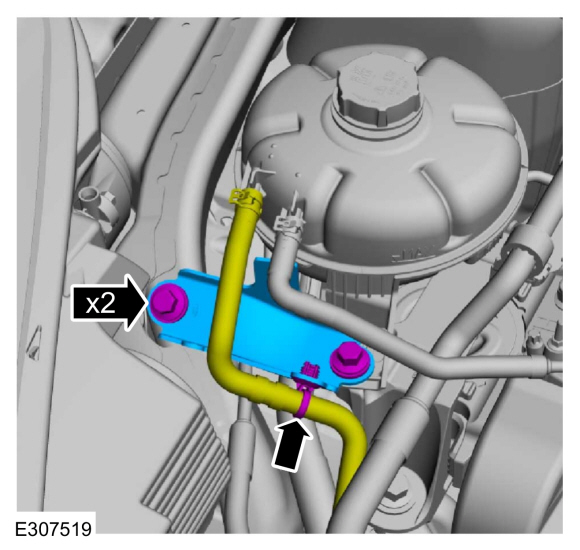

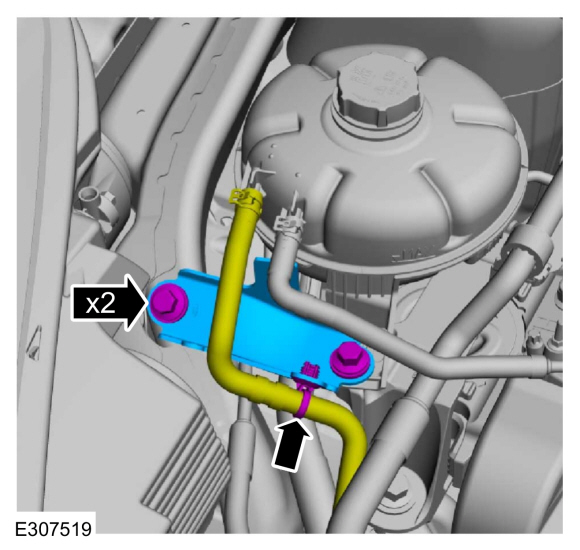

Detach the coolant hose retainer.

-

Remove the bolts and the degas bottle support bracket.

-

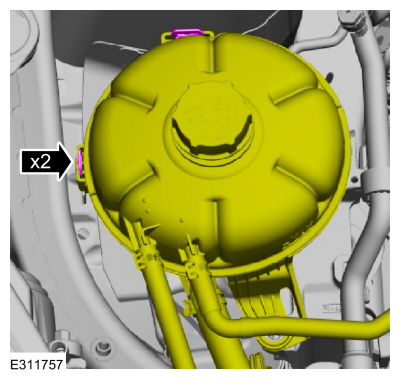

Release the tabs and position the degas bottle aside.

-

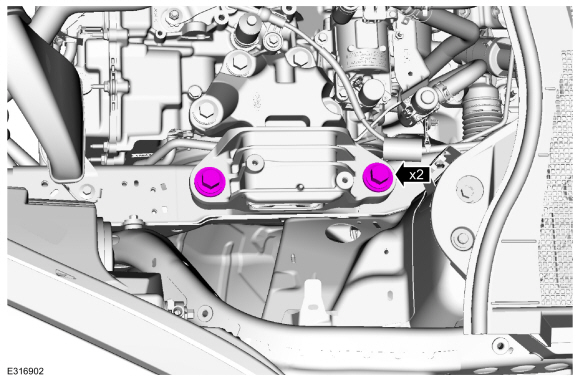

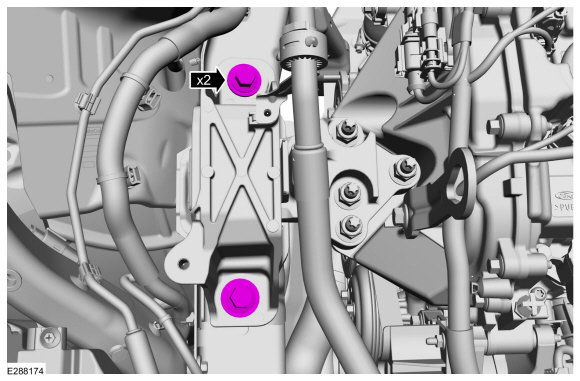

Loosen, but do not remove the engine mount bolts.

-

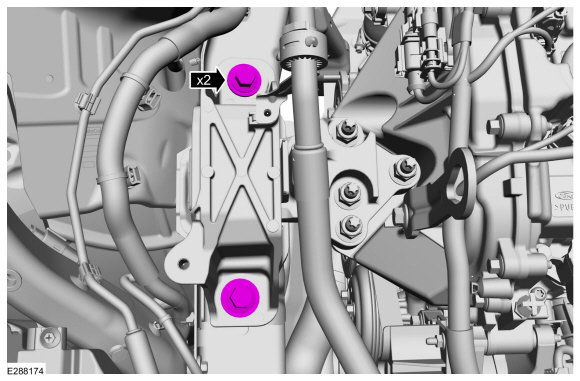

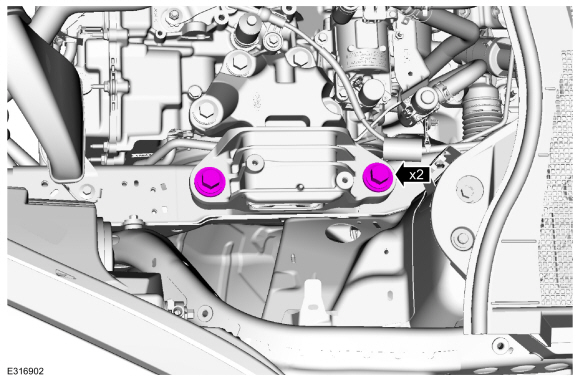

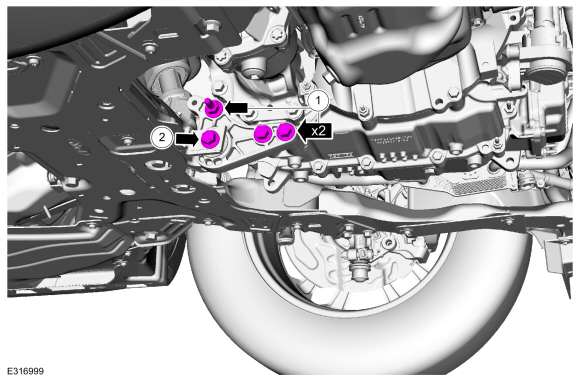

Loosen, but do not remove the transmission mount bolts.

-

NOTE:

Do not twist or strain the powertrain/drivetrain mounts or damage to the mounts may occur.

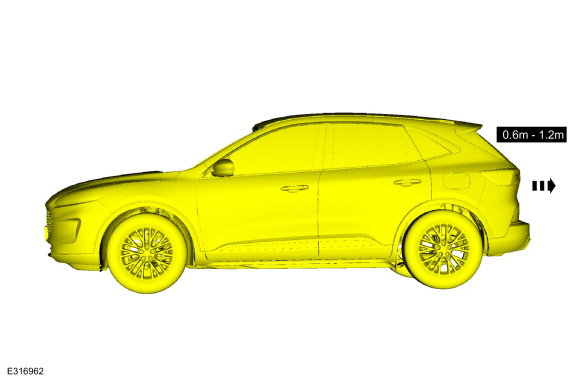

Start the vehicle and move it forward 0.6 m (1.97 ft) - 1.2 m (3.94 ft).

-

NOTE:

Do not twist or strain the powertrain/drivetrain mounts or damage to the mounts may occur.

Move the vehicle in reverse the same distance 0.6 m (1.97 ft) - 1.2 m (3.94 ft).

-

Tighten the transmission mount bolts.

Torque:

Stage 1:

103 lb.ft (140 Nm)

Stage 2:

120°

-

Tighten the engine mount bolts.

Torque:

129 lb.ft (175 Nm)

-

Position the degas bottle on the tabs.

-

-

Install the degas bottle support bracket and the bolts.

-

Attach the coolant hose retainer.

-

-

Tighten the bolts and studbolt.

Torque:

81 lb.ft (110 Nm)

-

Tighten the bolt.

Torque:

129 lb.ft (175 Nm)

-

Install the bracket and the nuts.

Torque:

35 lb.ft (47 Nm)

-

Install the undershield and fasteners.

-

Test the system for normal operation.

Check

NOTE:

Refer to the appropriate Section 303-01 for the specifications.

NOTE:

The cylinder bore must be within the specifications for taper and out-of-round before fitting a piston...

Special Tool(s) /

General Equipment

Plastic Scraper

Nylon Bristle Disk

Plastic Razor Blade

Lint-Free Towel

Isopropyl Alcohol – 90 Percent Minimum

Materials

Name

Specification

Motorcraft® Silicone Gasket RemoverZC-30-A, AZC-30-C

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Motorcraft® Engine Shampoo and DegreaserZC-20, AZC-20..

Other information:

Lincoln Automotive Financial Services offers

a full range of financing and lease plans to

help you acquire your vehicle. We are

dedicated to providing answers, information

and a truly extraordinary experience.

Use the options below to contact us with

questions about your account or financing

and we will respond promptly:

Web Address

www.credit.lincoln.com

Phone: 1-888-498-8801

Mail: Lincoln ..

Special Tool(s) /

General Equipment

Interior Trim Remover

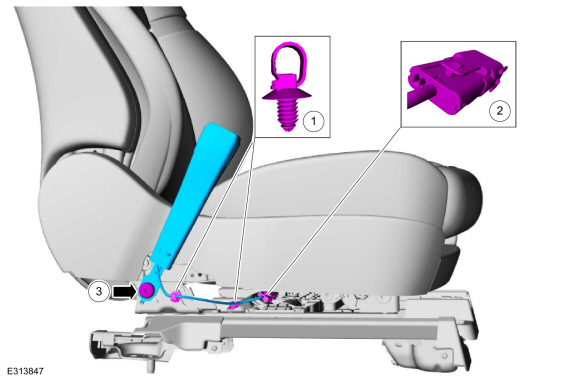

Removal

NOTE:

LH (left hand) shown, RH (right hand) similar.

NOTE:

Removal steps in this procedure may contain installation details.

Remove the loadspace trim panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Remove the C-pillar trim pan..

General Procedures - Piston Selection

General Procedures - Piston Selection General Procedures - RTV Sealing Surface Cleaning and Preparation

General Procedures - RTV Sealing Surface Cleaning and Preparation