Lincoln Corsair: Engine System - General Information / General Procedures - Intake Manifold Vacuum Test

Lincoln Corsair 2020-2026 Service Manual / Powertrain / Engine / Engine System - General Information / General Procedures - Intake Manifold Vacuum Test

-

Bring the engine to normal operating temperature. Connect

the Vacuum/Pressure Tester to the intake manifold. Run the engine at the

specified idle speed.

-

The vacuum gauge should read between 51-74 kPa (15-22 in-Hg)

depending upon the engine condition and the altitude at which the test

is conducted. Subtract 4.0193 kPa (1 in-Hg) from the specified reading

for every 304.8 m (1,000 feet) of elevation above sea level.

-

The reading should be steady. If necessary, adjust the gauge

damper control (where used) if the needle is fluttering rapidly. Adjust

the damper until the needle moves easily without excessive flutter.

Intake Manifold Vacuum Test - Interpreting Vacuum Gauge Readings

-

A careful study of the vacuum gauge reading while the

engine is idling will help pinpoint trouble areas. Always conduct other

appropriate tests before arriving at a final diagnostic decision. Vacuum

gauge readings, although helpful, must be interpreted carefully.

-

Most vacuum gauges have a normal band indicated on the

gauge face. The following are potential gauge readings. Some are normal;

others should be investigated further.

-

The following are potential gauge readings. Some are normal; others should be investigated further.

Visual Inspection Chart

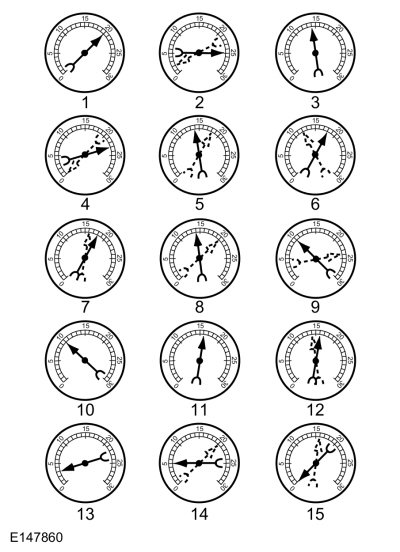

Mechanical - 1. NORMAL READING: Needle between 51-74 kPa (15-22 in-Hg) and holding steady.

- 2. NORMAL READING DURING RAPID ACCELERATION AND DECELERATION: When the engine is rapidly accelerated (dotted needle), the needle will drop to a low reading (not to zero). When the throttle is suddenly released, the needle will snap back up to a higher than normal figure.

- 3. NORMAL FOR HIGH-LIFT CAMSHAFT WITH LARGE OVERLAP: The needle will register as low as 51 kPa (15 in-Hg) but will be relatively steady. Some oscillation is normal.

- 4. WORN RINGS OR DILUTED OIL: When the engine is accelerated (dotted needle), the needle drops to 0 kPa (0 in-Hg). Upon deceleration, the needle runs slightly above 74 kPa (22 in-Hg).

- 5. STICKING VALVES: When the needle (dotted) remains steady at a normal vacuum but occasionally flicks (sharp, fast movement) down and back about 13 kPa (4 in-Hg), one or more valves may be sticking.

- 6. BURNED OR WARPED VALVES: A regular, evenly-spaced, downscale flicking of the needle indicates one or more burned or warped valves. Insufficient valve clearance will also cause this reaction.

- 7. POOR VALVE SEATING: A small but regular downscale flicking can mean one or more valves are not seating.

- 8. WORN VALVE GUIDES: When the needle oscillates over about a 13 kPa (4 in-Hg) range at idle speed, the valve guides could be worn. As engine speed increases, the needle will become steady if guides are responsible.

- 9. WEAK VALVE SPRINGS: When the needle oscillation becomes more violent as engine rpm is increased, weak valve springs are indicated. The reading at idle could be relatively steady.

- 10. LATE VALVE TIMING: A steady but low reading could be caused by late valve timing.

- 11. IGNITION TIMING RETARDING: Retarded ignition timing will produce a steady but somewhat low reading.

- 12. INSUFFICIENT SPARK PLUG GAP: When spark plugs are gapped too close, a regular, small pulsation of the needle can occur.

- 13. INTAKE LEAK: A low, steady reading can be caused by an intake manifold or TB gasket leak.

- 14. BLOWN HEAD GASKET: A regular drop of fair magnitude can be caused by a blown head gasket or warped cylinder head-to-cylinder block surface.

- 15. RESTRICTED EXHAUST SYSTEM: When the engine is first started and is idled, the reading may be normal, but as the engine rpm is increased, the back pressure caused by a clogged muffler, kinked tailpipe or other concerns will cause the needle to slowly drop to 0 kPa (0 in-Hg). The needle then may slowly rise. Excessive exhaust clogging will cause the needle to drop to a low point even if the engine is only idling.

|

-

When vacuum leaks are indicated, search out and correct

the cause. Excess air leaking into the system will upset the fuel

mixture and cause concerns such as rough idle, missing on acceleration

or burned valves. If the leak exists in an accessory unit, the unit will

not function correctly. Always fix vacuum leaks.

General Procedures - Exhaust Manifold Cleaning and Inspection

General Procedures - Exhaust Manifold Cleaning and Inspection

Special Tool(s) /

General Equipment

Feeler Gauge

Cleaning

Clean the exhaust manifold using a suitable solvent. Use

a plastic scraping tool to clean the gasket sealing surfaces...

General Procedures - Oil Consumption Test

General Procedures - Oil Consumption Test

Nearly all engines consume oil, which is essential for

normal lubrication of the cylinder bore walls and pistons and rings.

Determining the level of oil consumption may require testing by

recording how much oil is being added over a given set of miles...

Other information:

Lincoln Corsair 2020-2026 Service Manual: Removal and Installation - Front Seat Cushion Extension Adjuster - Vehicles With: Multi-Contour Seats

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the front seat. Refer to: Front Seat (501-10A Front Seats, Removal and Installation). Remove the front seat side shield screws. Remove the LH front seat side shield...

Lincoln Corsair 2020-2026 Service Manual: Description and Operation - Engine - Overview

Overview The 2.0L GTDI engine which may also be described with these terms: GTDI - Gasoline turbocharged direct injection DI - Direct injection TIVCT - Twin independent Variable Camshaft Timing I4 - 4 cylinder engine 16 V - 4 valves per cylinder 4V - 4 valves per cylinder, 16 valves total 2...

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Capacities and Specifications - 2.0L

- Overhaul - Main Control Valve Body

- Programming the Garage Door Opener to Your Hand-Held Transmitter

- New on site

- Most important about car

Creating a Vehicle Wi-Fi Hotspot

You can create a Wi-Fi hotspot in your vehicle and allow devices to connect to it for access to the Internet.

Select the settings option on

the

feature bar.

Select the settings option on

the

feature bar.

Copyright © 2026 www.licorsair.com