Lincoln Corsair: Automatic Transmission - Automatic Transmission – HF45 / Removal and Installation - Roll Restrictor RH

Special Tool(s) /

General Equipment

Removal

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Roll Restrictor RH (307-01B Automatic Transmission - Automatic Transmission – HF45, Removal and Installation).

-

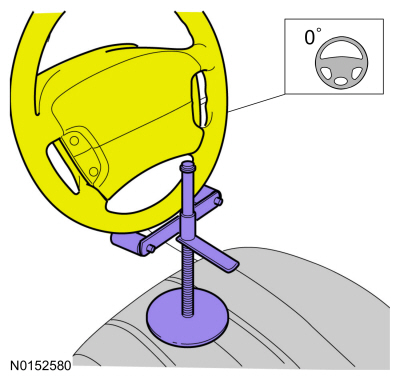

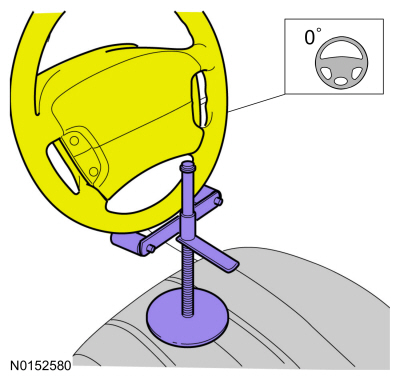

Using a holding device, hold the steering wheel in the straight-ahead position.

-

-

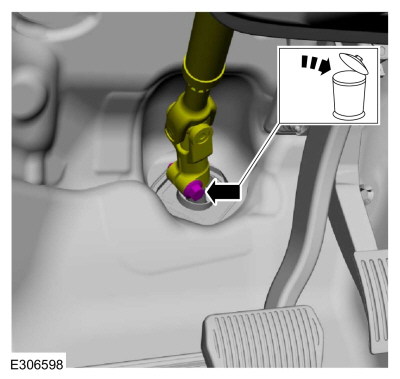

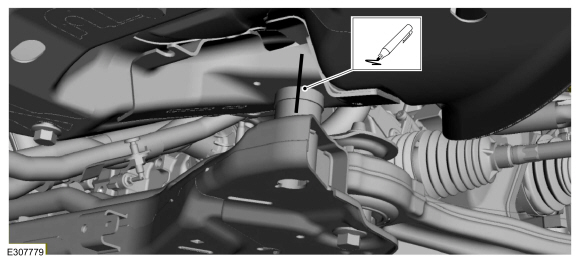

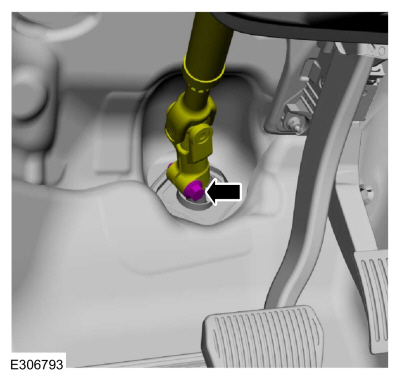

Remove the bolt and discard.

-

Position steering column shaft aside.

-

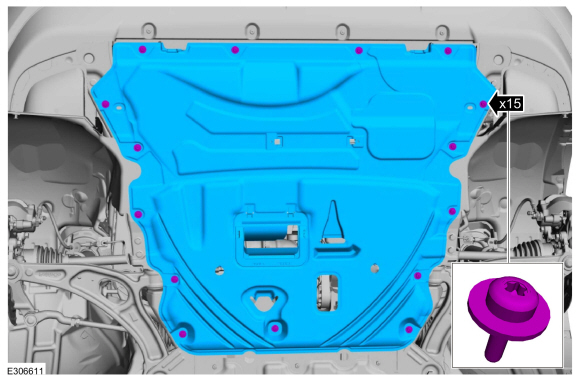

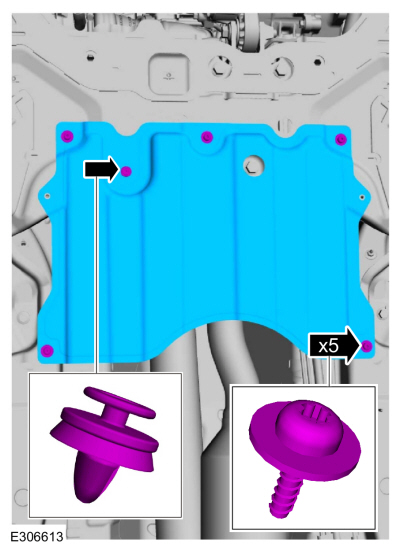

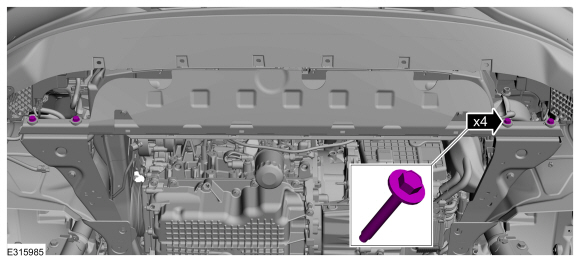

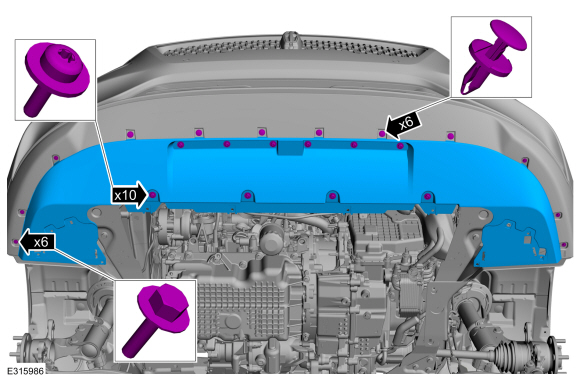

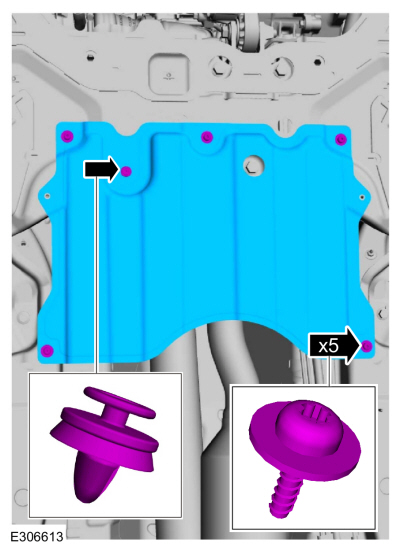

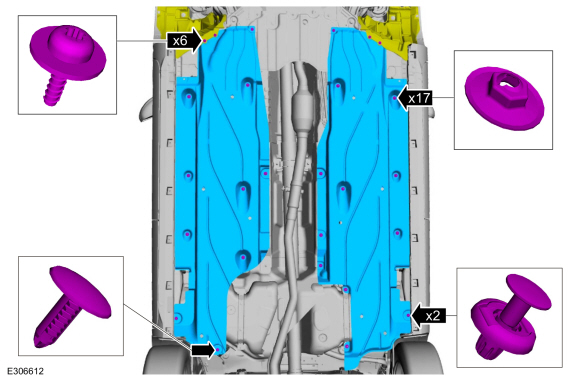

Remove the retainers and the underbody shield.

-

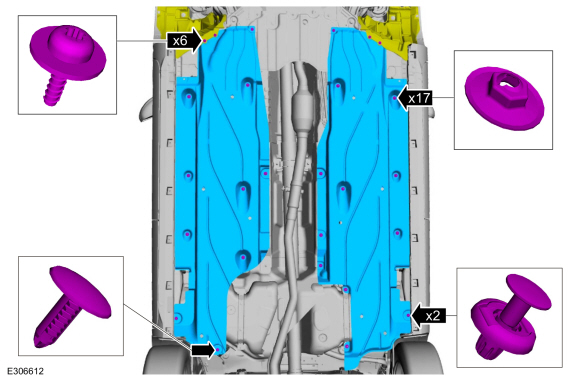

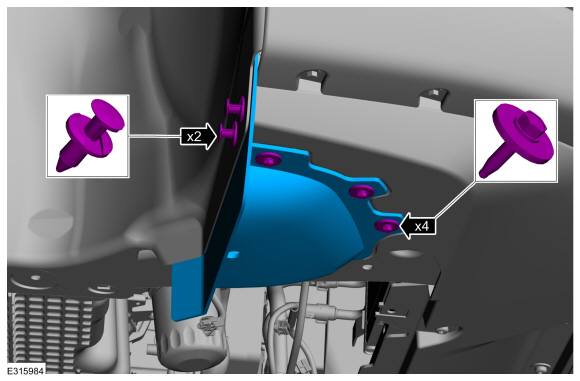

Remove the retainers and the underbody shields.

-

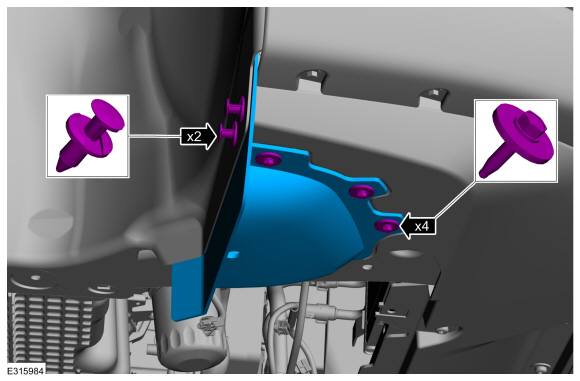

Remove the retainers and the underbody shield.

-

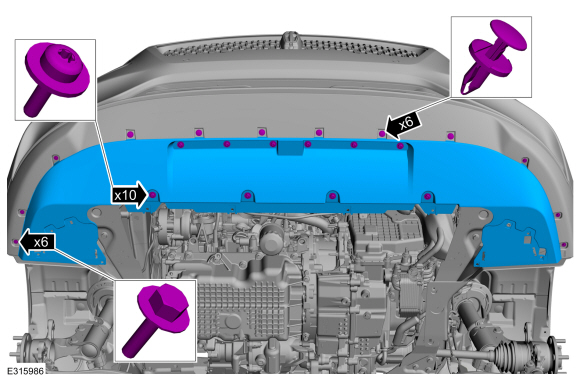

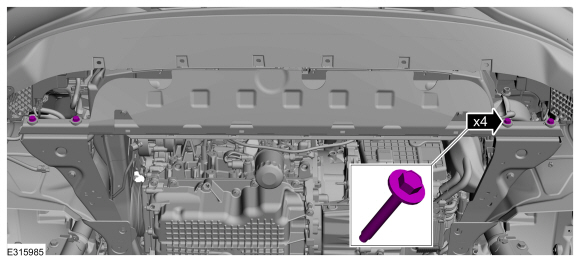

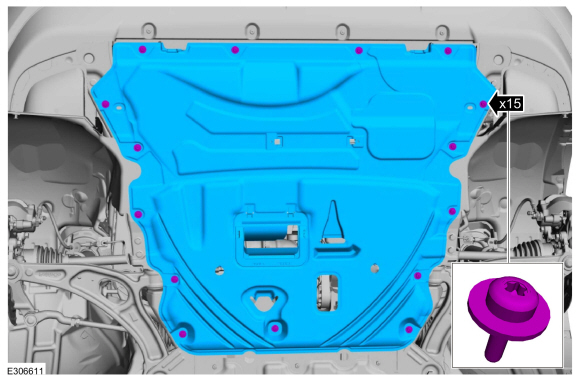

On both sides, remove the retainers and the front underbody shield.

-

Remove the retainers and the front underbody shield.

-

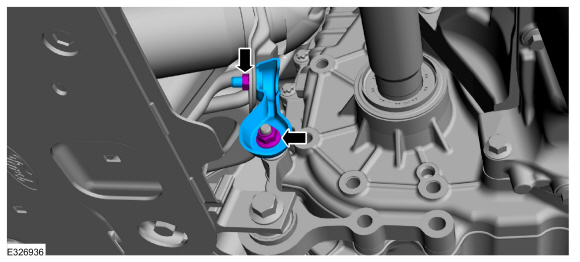

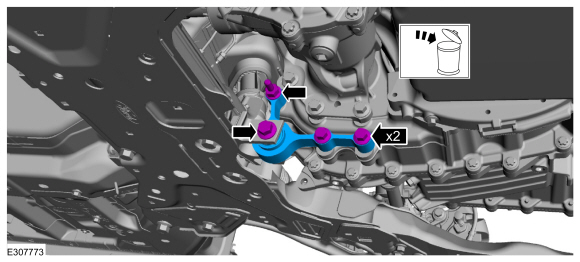

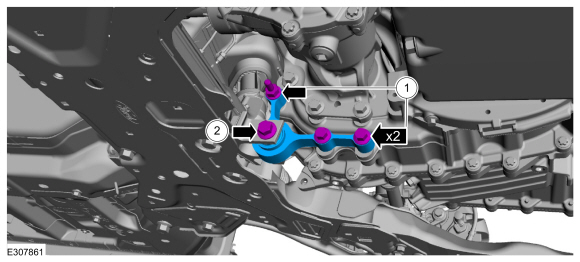

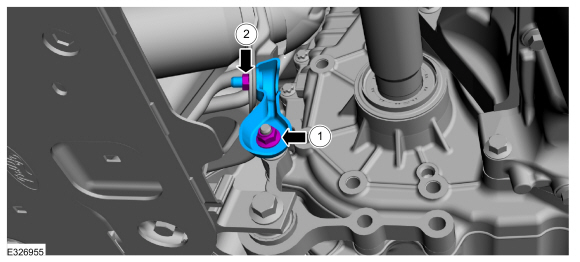

Remove the nuts and the bracket.

-

Remove and discard the roll restrictor bracket bolts and remove the bracket.

-

Remove and discard the roll restrictor bolts.

-

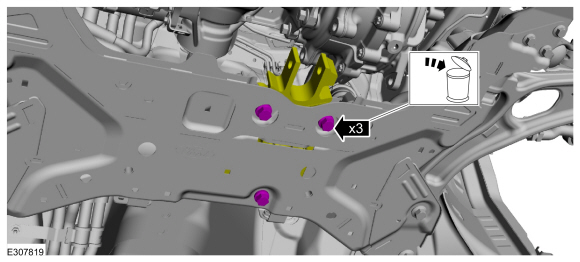

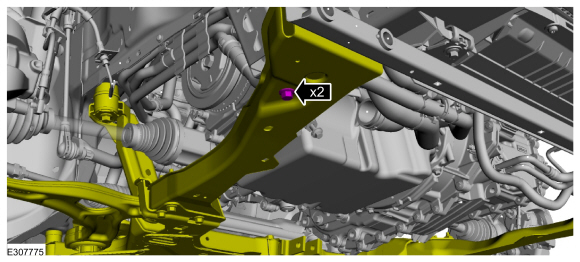

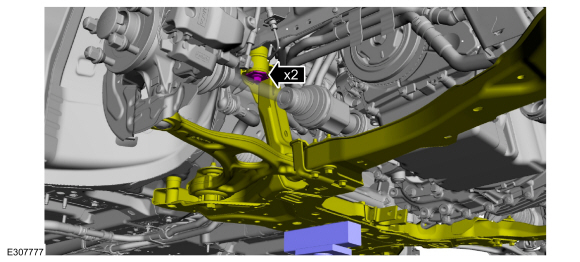

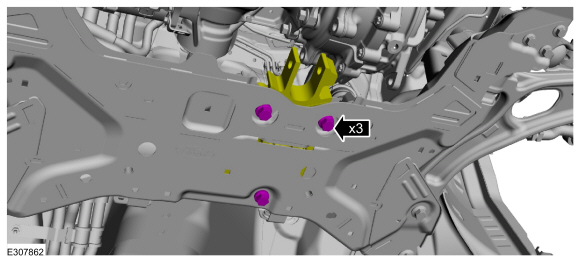

Remove the subframe support bracket bolts.

-

-

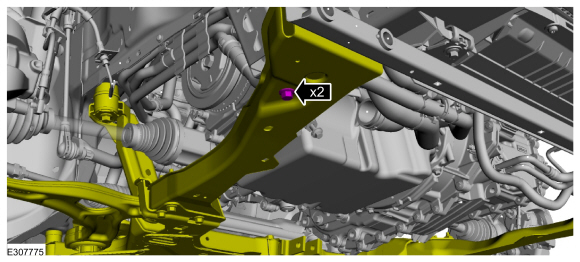

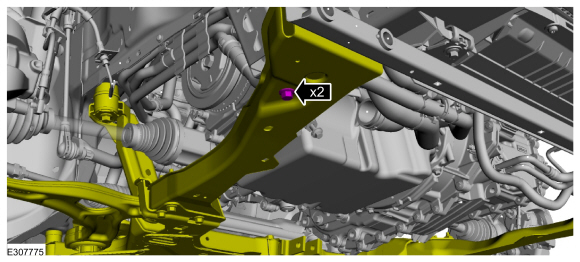

Remove and discard the rearward subframe bolts.

-

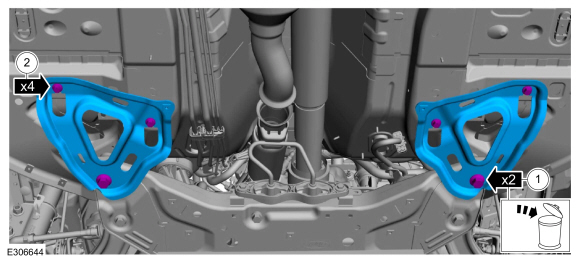

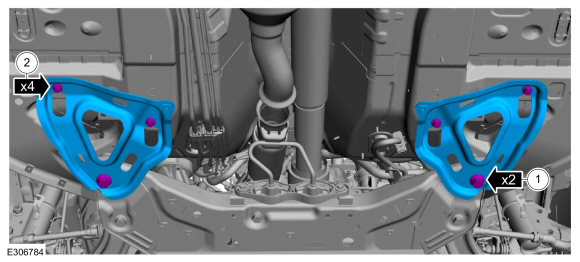

Remove the bolts and the subframe brackets.

-

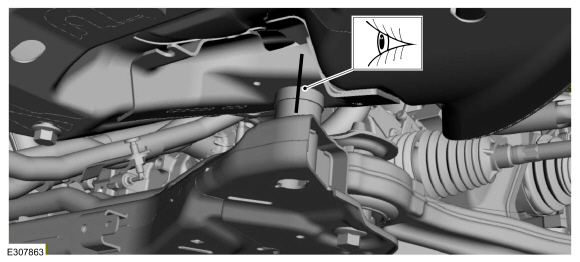

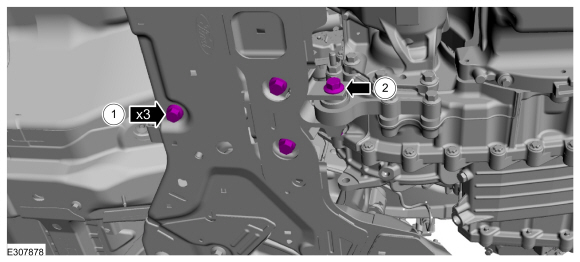

On both sides, index-mark the subframe to the body.

-

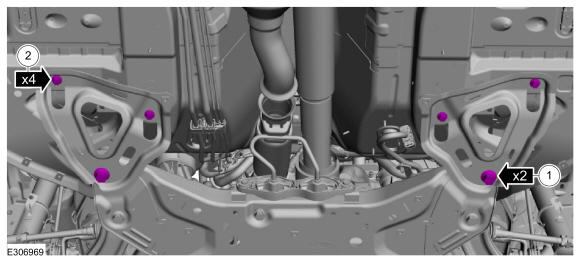

On both sides, remove the front subframe bolts.

-

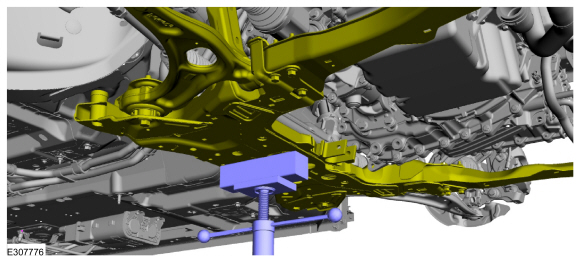

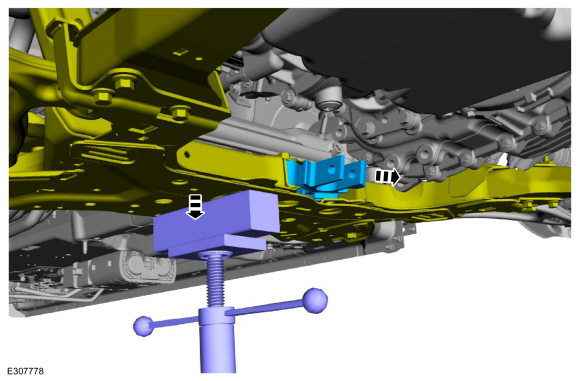

Support the subframe with a screw jack.

Use the General Equipment: Wooden Block

-

NOTE:

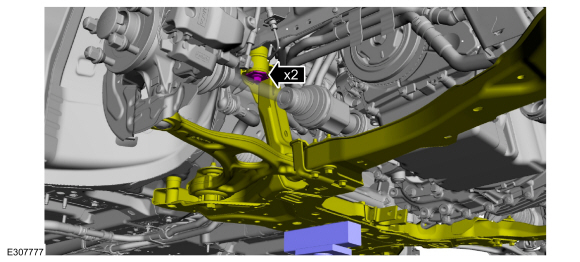

Do not remove the bolts.

On both sides, loosen the subframe bolts.

-

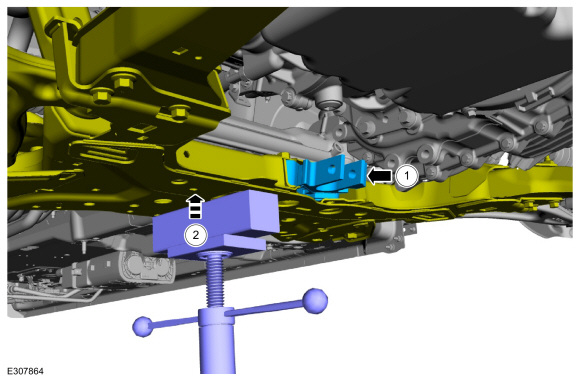

NOTE:

Lower the subframe far enough to remove the roll restrictor without interference from the transmission.

Using a screw jack, lower the subframe and remove the roll restrictor.

Use the General Equipment: Wooden Block

Installation

-

-

Install the roll restrictor.

-

Raise the subframe.

-

On both sides, install the front subframe bolts finger tight.

-

-

Install the subframe brackets and the new rearward subframe bolts finger tight.

-

Install the subframe bracket bolts finger tight.

-

On both sides, align index-mark made during removal.

-

On both sides, tighten the subframe bolts.

Torque:

85 lb.ft (115 Nm)

-

On both sides, tighten the front subframe bolts.

Torque:

85 lb.ft (115 Nm)

-

-

Tighten the subframe bolts in two stages.

Torque:

Stage 1:

159 lb.ft (215 Nm)

Stage 2:

60°

-

Tighten the subframe bracket bolts.

Torque:

46 lb.ft (63 Nm)

-

Install the subframe support bracket bolts.

Torque:

22 lb.ft (30 Nm)

-

Install new roll restrictor bolts finger tight.

-

-

Install the roll restrictor bracket, new bolts and studbolt.

Torque:

81 lb.ft (110 Nm)

-

Install a new roll restrictor bolt finger tight.

-

-

Tighten the roll restrictor bolts.

Torque:

52 lb.ft (70 Nm)

-

Tighten the roll restrictor bolt.

Torque:

129 lb.ft (175 Nm)

-

Install the bracket and the nuts.

Torque:

1:

35 lb.ft (47 Nm)

2:

18 lb.ft (25 Nm)

-

Install the retainers and the front underbody shield.

-

On both sides, install the retainers and the front fender air deflector.

-

Install the underbody shield and the retainers.

Torque:

22 lb.in (2.5 Nm)

-

Install the underbody shields and the retainers.

Torque:

22 lb.in (2.5 Nm)

-

Install the underbody shield and the retainers.

Torque:

13 lb.in (1.5 Nm)

-

Position steering column shaft and install a new bolt.

Torque:

46 lb.ft (63 Nm)

-

Remove the holding device.

Removal

To remove the ISC (inverter system controller).

Refer to: Inverter System Controller [SOBDMC] (303-14D Electric Powertrain Control, Removal and Installation)...

Special Tool(s) /

General Equipment

307-805Alignment Pins (2)

Ford Diagnostic Equipment

Removal

NOTE:

This step is only necessary when installing a new transmission or ISC (Inverter System Controller)...

Other information:

Removal

Remove the steering column shrouds.

Refer to: Steering Column Shrouds (501-05 Interior Trim and Ornamentation, Removal and Installation).

If equipped.

Remove the steering column control switch.

Refer to: Steering Column Control Switch (211-05 Steering Wheel and Column Electrical Components, Removal and Installation)...

Removal

Remove the steering column shrouds.

Refer to: Steering Column Shrouds (501-05 Interior Trim and Ornamentation, Removal and Installation).

NOTE:

Make sure that the component terminals are not bent or damaged.

Remove the retainers...

Removal and Installation - Inverter System Controller

Removal and Installation - Inverter System Controller Removal and Installation - Transmission

Removal and Installation - Transmission