Lincoln Corsair: Automatic Transmission - Automatic Transmission – HF45 / Disassembly - Transmission - Plug-In Hybrid Electric Vehicle (PHEV)

Special Tool(s) /

General Equipment

|

307-163

(T86P-70043-A)

Remover, Stator Case Bearing

TKIT-1986-LM

TKIT-1986-F |

|

307-586

Differential bearing cup remover

TKIT-2006UF-FLM

TKIT-2006UF-ROW |

|

307-741

Spring Compressor, F Clutch |

|

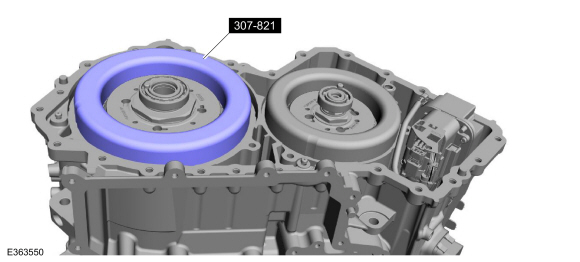

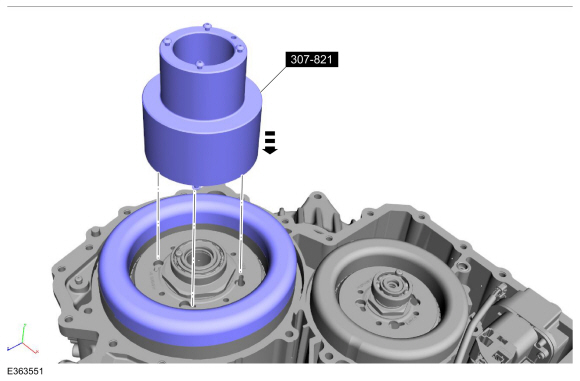

307-821

Motor Rotor Remover Installer |

|

308-001

(T58L-101-B)

Remover, Pilot Bearing |

| Hydraulic Press |

| Puller |

| Punch |

| Wooden Block |

-

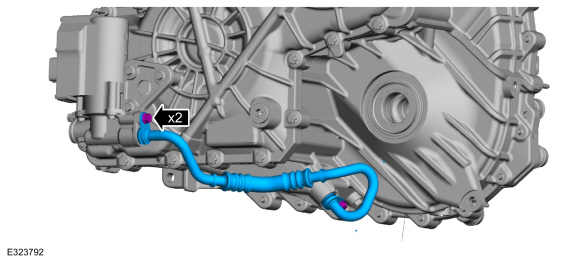

Remove the bolts the and transmission fluid tube.

-

Inspect the transmission and the auxiliary pump to be sure

the transmission fluid tube seal and backing ring were removed with the

transmission fluid tube and are not stuck in the transmission or

auxiliary pump. If the transmission fluid tube seal or backing ring are

stuck in the transmission or auxiliary pump, remove the seal and backing

ring.

-

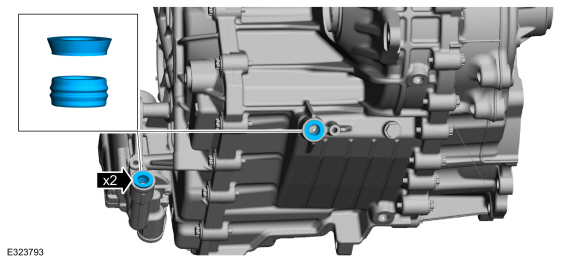

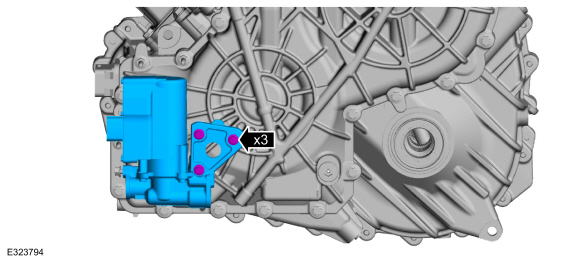

Remove the bolts and the transmission fluid auxiliary pump.

-

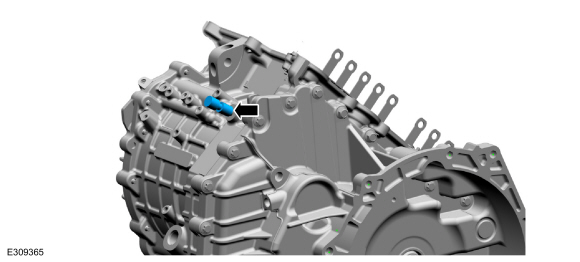

Remove the vent assembly.

-

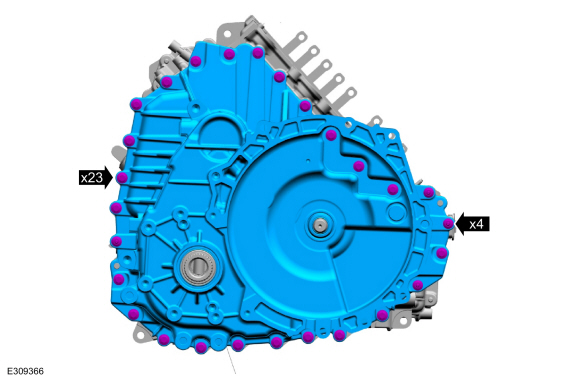

NOTE:

Note the location of the stud bolts for assembly.

Remove the damper housing bolts and the studbolts.

-

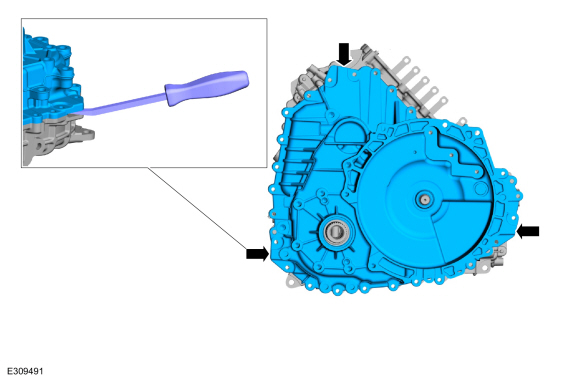

Using a prybar, pry the damper housing at the indicated areas to remove the housing.

-

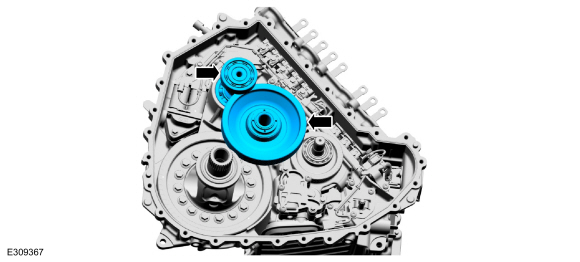

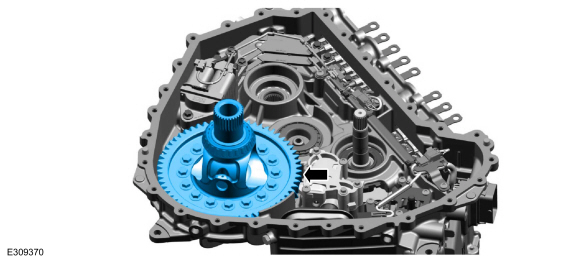

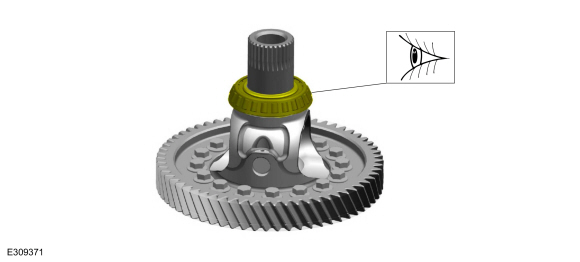

Remove the transfer shaft gear assembly and the traction motor drive gear assembly.

-

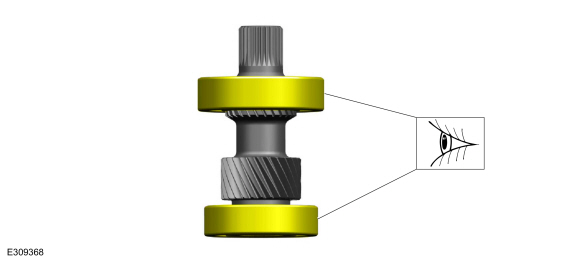

Replace the transfer shaft and gear assembly and install new bearing races if the bearings are damaged.

-

Replace the transfer shaft and gear assembly and install new bearings if the bearings are damaged.

-

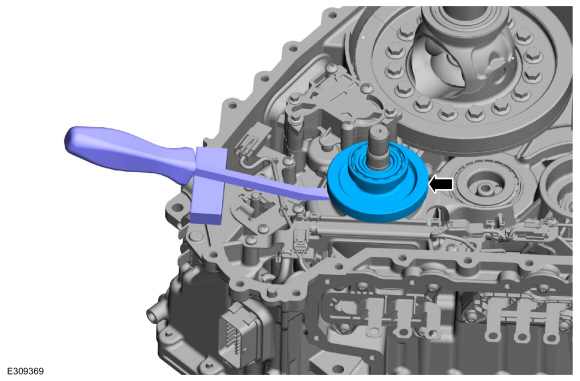

Using a prybar and a block of wood, remove the final drive input gear assembly.

Use the General Equipment: Wooden Block

-

Replace the final drive input gear assembly if the bearings are damaged.

-

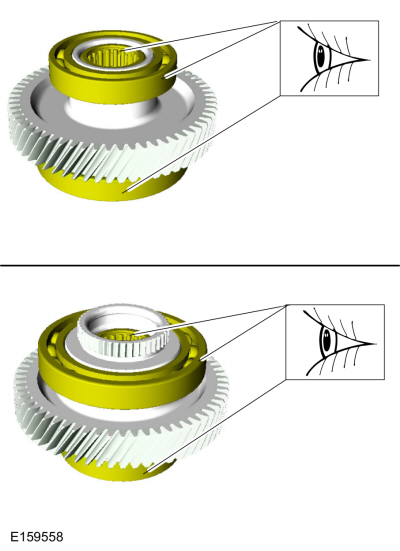

Remove the differential carrier gear assembly.

-

Inspect the differential bearing for damage, replace if necessary.

-

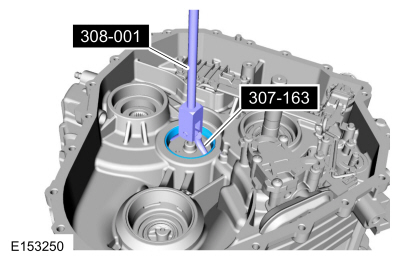

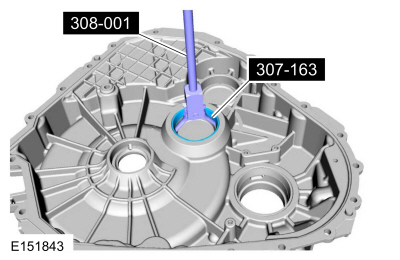

Using the special tools, remove the transmission case side transfer gear bearing cup.

Use Special Service Tool: 308-001

(T58L-101-B)

Remover, Pilot Bearing.

, 307-163

(T86P-70043-A)

Remover, Stator Case Bearing.

-

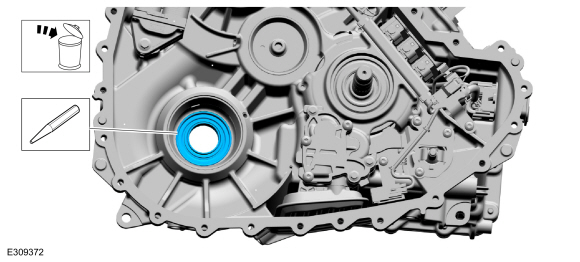

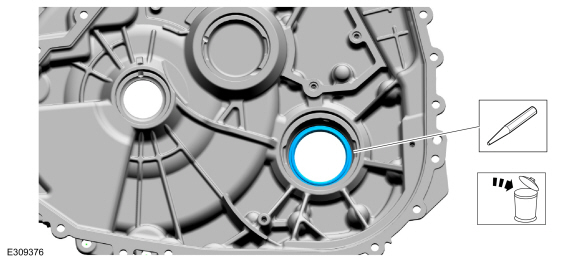

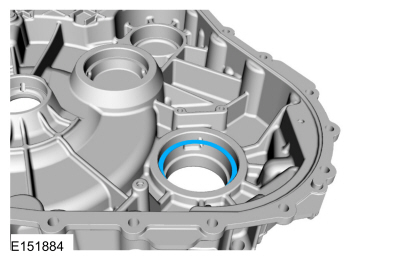

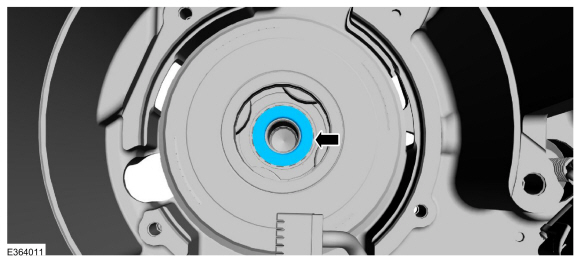

Remove and discard the LH halfshaft seal.

Use the General Equipment: Punch

-

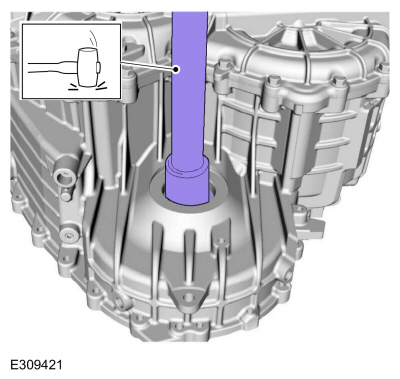

-

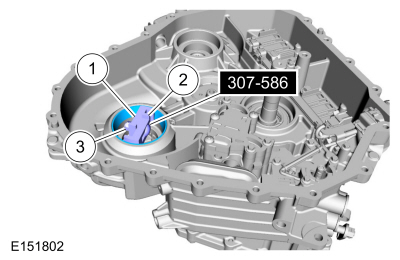

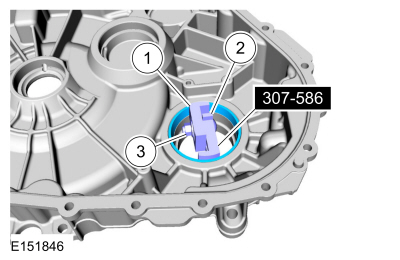

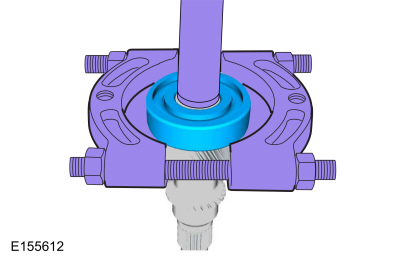

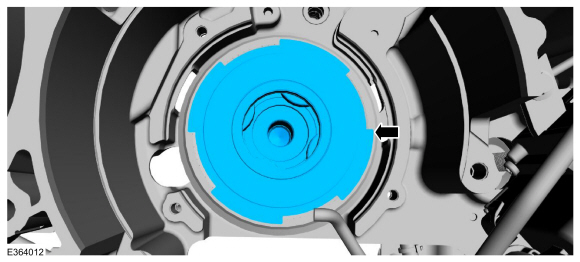

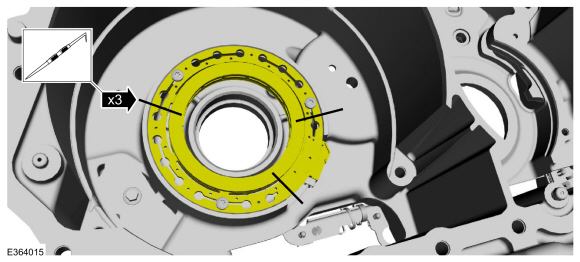

Position the Differential Bearing Cup Remover 307-586 in

the transmission case with the tabs on the Differential Bearing Cup

Remover 307-586 aligned with the slots in the transmission case.

Use Special Service Tool: 307-586

Differential bearing cup remover.

-

Expand the Differential Bearing Cup Remover 307-586 by hand.

-

While holding the Differential Bearing Cup Remover

307-586 in the expanded position with the tabs in the slots of the

transmission case, tighten the nut.

-

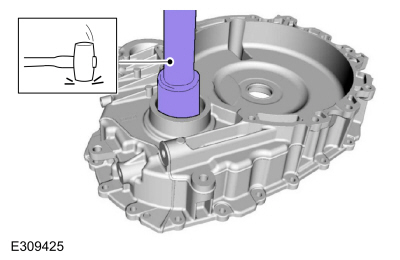

Using a hammer and a drift, remove the differential bearing cup.

Use Special Service Tool: 307-586

Differential bearing cup remover.

-

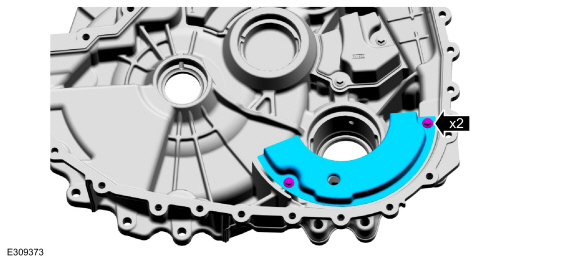

Remove the retainers and the transmission fluid sump baffle.

-

Remove the retainers and the transmission fluid collector plate.

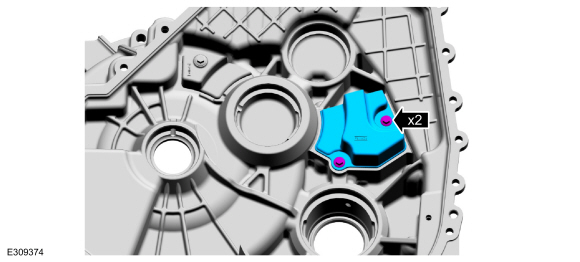

-

Remove the retainer and the transmission fluid collector plate.

-

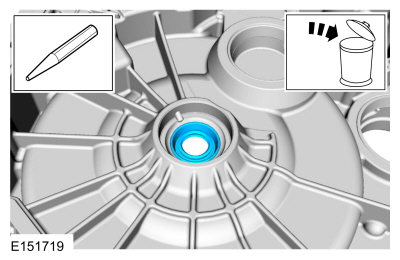

Remove and discard the RH halfshaft seal.

Use the General Equipment: Punch

-

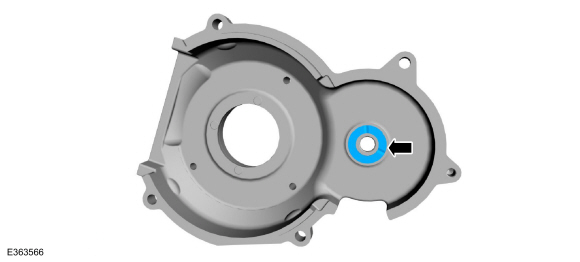

Remove and discard the input shaft seal.

Use the General Equipment: Punch

-

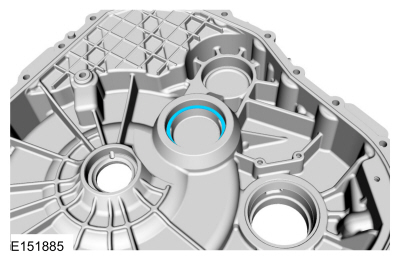

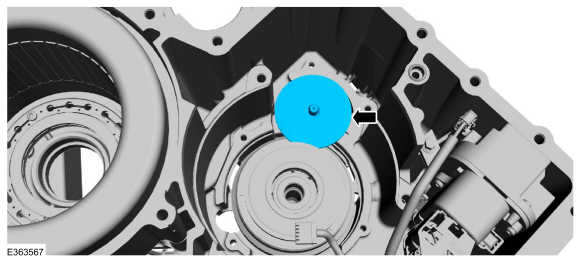

Remove the damper housing side transfer gear bearing cup.

Use Special Service Tool: 308-001

(T58L-101-B)

Remover, Pilot Bearing.

, 307-163

(T86P-70043-A)

Remover, Stator Case Bearing.

-

Remove the transfer shaft preload shim.

-

-

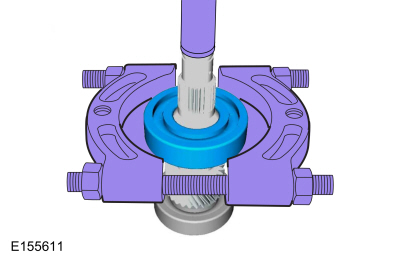

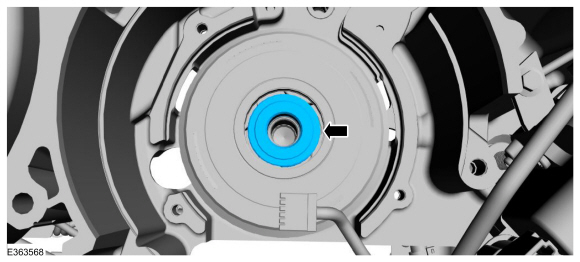

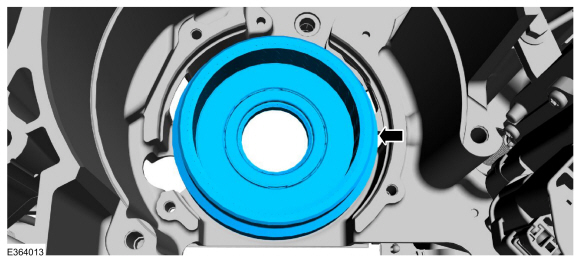

Position the Differential Bearing Cup Remover 307-586 in

the damper housing with the tabs on the Differential Bearing Cup

Remover 307-586 aligned with the slots in the damper housing.

Use Special Service Tool: 307-586

Differential bearing cup remover.

-

Expand the Differential Bearing Cup Remover 307-586 by hand.

-

While holding the Differential Bearing Cup Remover

307-586 in the expanded position with the tabs in the slots of the

damper housing, tighten the nut.

-

Using a hammer and a drift, remove the damper housing side differential bearing cup.

Use Special Service Tool: 307-586

Differential bearing cup remover.

-

Remove the differential preload shim.

-

Remove the traction motor drive gear rear bearing from the traction motor drive gear.

Use the General Equipment: Puller

Use the General Equipment: Hydraulic Press

-

Remove the traction motor drive gear front bearing from the traction motor drive gear.

Use the General Equipment: Puller

Use the General Equipment: Hydraulic Press

-

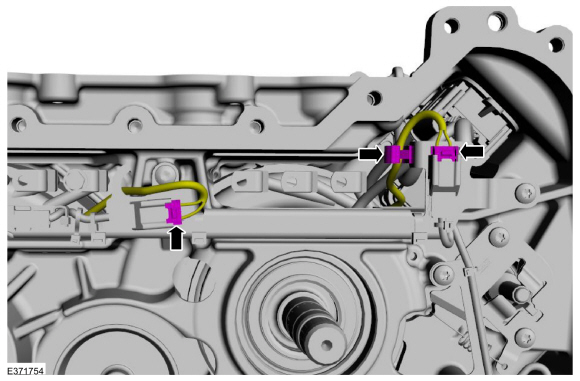

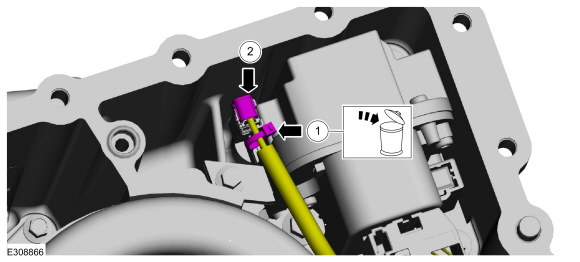

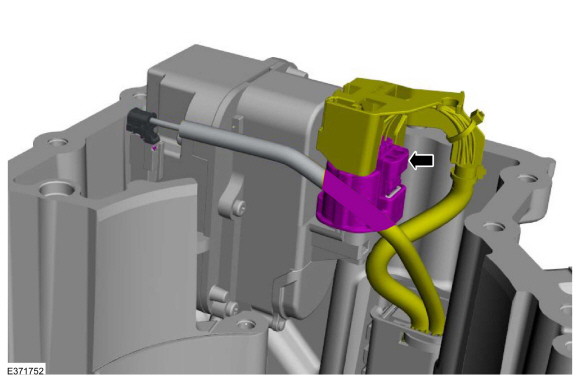

Remove the transmission high voltage terminals.

Refer to: Transmission High Voltage Terminals (307-01B Automatic

Transmission - Automatic Transmission – HF45, Disassembly and Assembly

of Subassemblies).

-

-

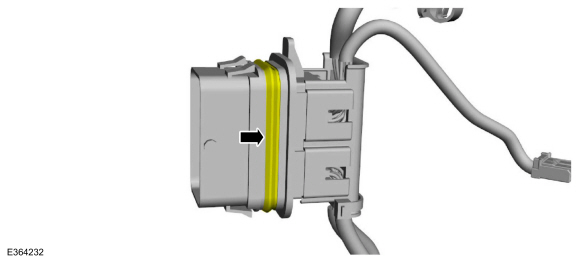

Disconnect the traction motor stator electrical connector.

-

Disconnect the generator/starter stator electrical connector.

-

Detach the wiring retainer.

-

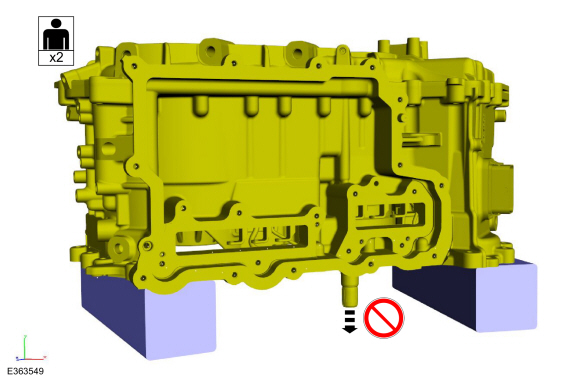

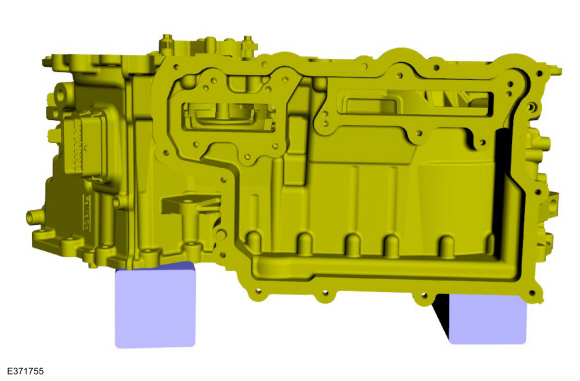

Position the transmission case on blocks of wood so the transmission input shaft doesn't contact the table surface.

-

Remove the transmission case cover.

Refer to: Transmission Case Cover (307-01B Automatic Transmission - Automatic Transmission – HF45, Removal and Installation).

-

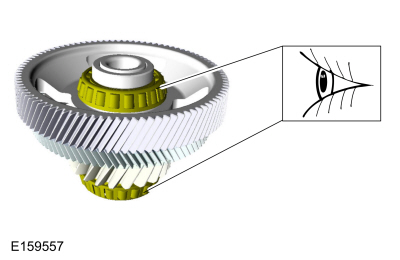

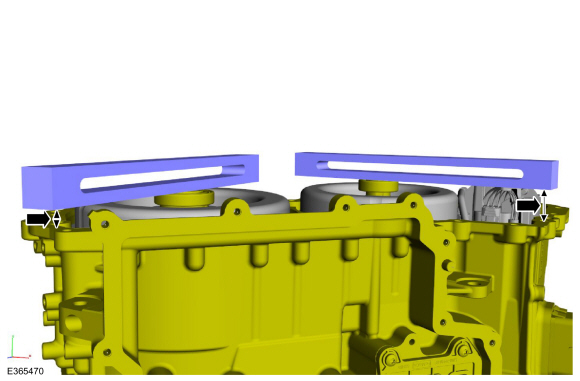

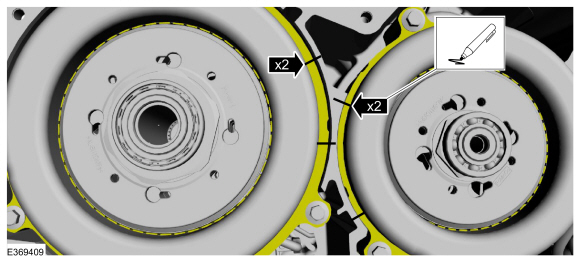

Using a straight edge, measure and record the distance

between the traction motor rotor and the transmission case surface. Then

measure and record the distance between the generator/starter rotor and

transmission case surface for reassembly.

-

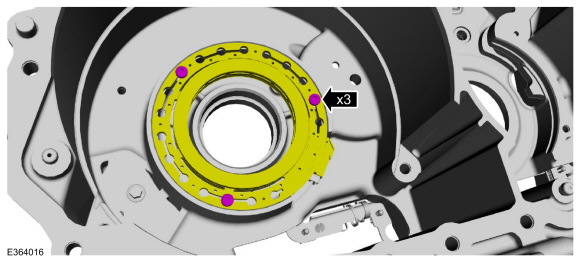

Mark the traction motor stator and the generator/starter

stator with the transmission case as indicated for correct installation.

-

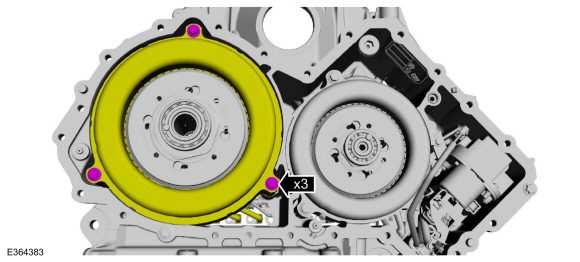

Remove the traction motor stator bolts.

-

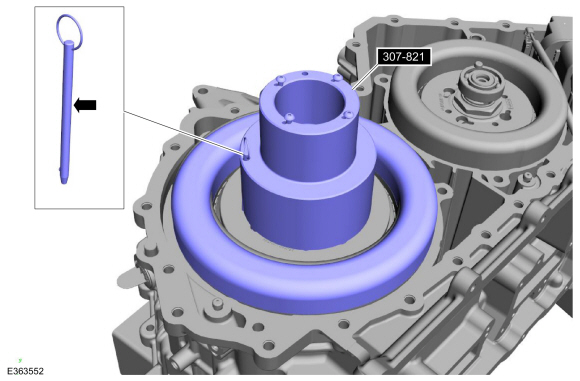

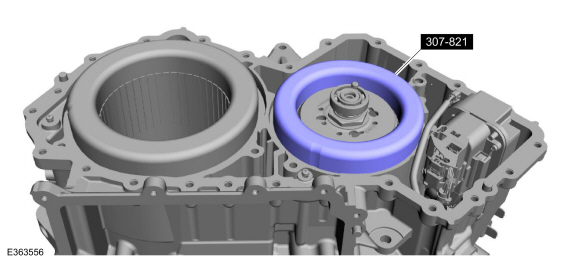

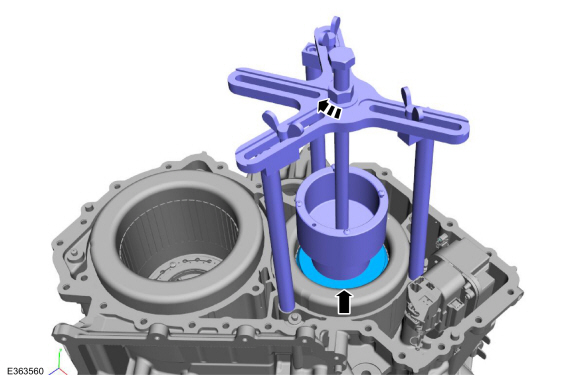

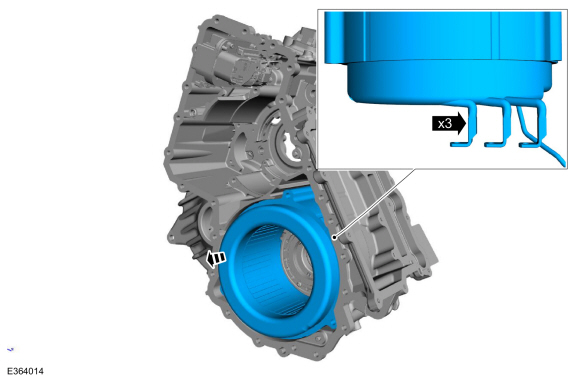

Install the special tool on the traction motor stator windings.

Use Special Service Tool: 307-821

Motor Rotor Remover Installer.

-

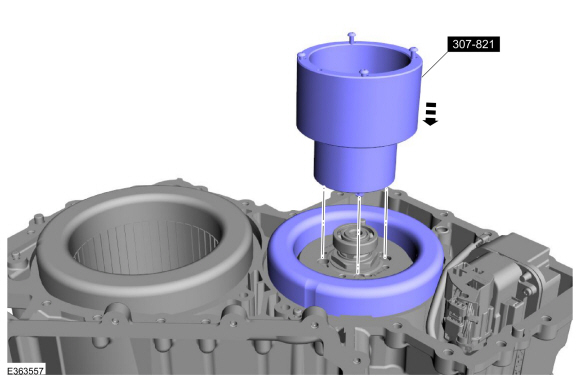

Install the special tool in the traction motor rotor slotted

holes and rotate counter-clockwise until special tool is secured.

Use Special Service Tool: 307-821

Motor Rotor Remover Installer.

-

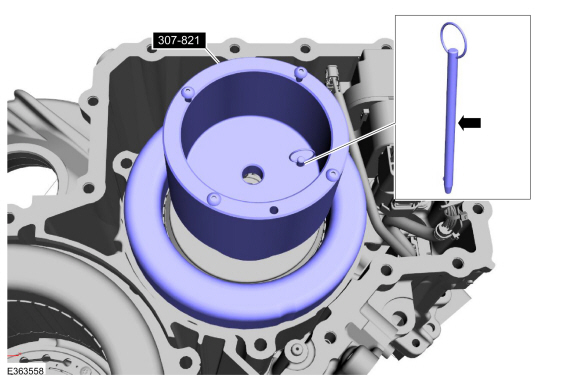

Install the pin in the special tool until it is fully seated in the rotor.

Use Special Service Tool: 307-821

Motor Rotor Remover Installer.

-

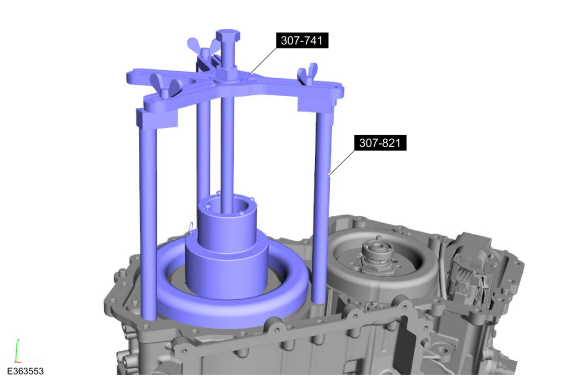

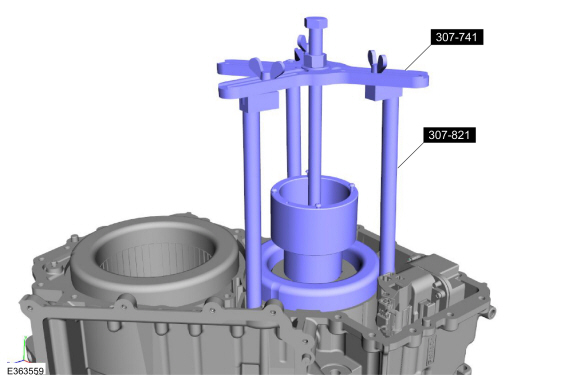

Install the special tools, thread draw bolt into special tool and tighten the wing nuts.

Use Special Service Tool: 307-741

Spring Compressor, F Clutch.

, 307-821

Motor Rotor Remover Installer.

-

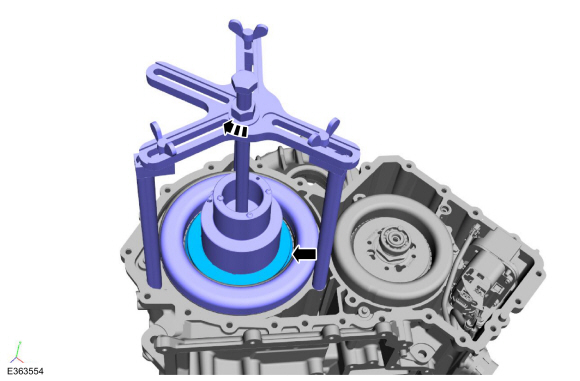

NOTICE:

Rotors are magnetized, only place rotors on a nonmetallic tray.

-

Remove the traction motor rotor by turning the nut on the draw bar.

-

When the rotor starts to turn in the stator, lift up on the special tool to remove the rotor.

-

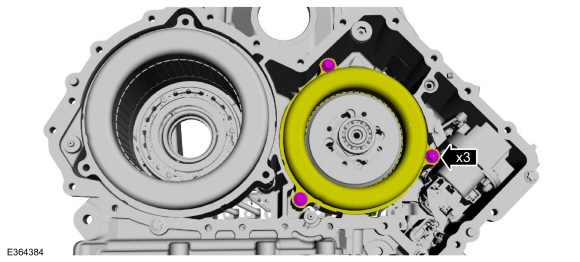

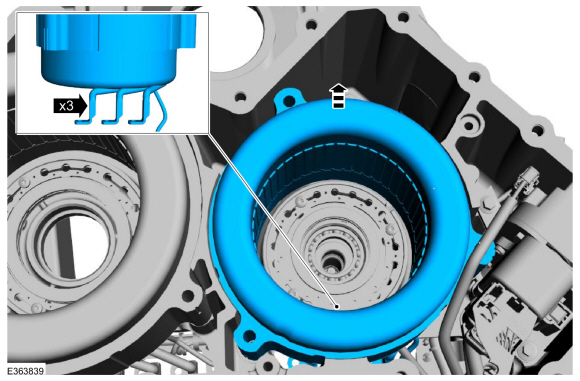

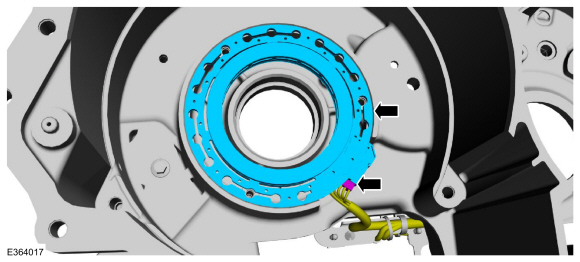

Remove the generator/starter stator bolts.

-

Install the special tool on the generator/starter stator windings.

Use Special Service Tool: 307-821

Motor Rotor Remover Installer.

-

Install the special tool in the generator/starter rotor

slotted holes and rotate counter-clockwise until special tool is

secured.

Use Special Service Tool: 307-821

Motor Rotor Remover Installer.

-

Install the pin in the special tool until it is fully seated in the rotor.

Use Special Service Tool: 307-821

Motor Rotor Remover Installer.

-

Install the special tools, thread draw bolt into special tool and tighten the wing nuts.

Use Special Service Tool: 307-741

Spring Compressor, F Clutch.

, 307-821

Motor Rotor Remover Installer.

-

NOTICE:

Rotors are magnetized, only place rotors on a

nonmetallic tray. Do not let the traction rotor and the

generator/starter rotor come in contact with each other or damage may

occur.

-

Remove the generator/starter rotor by turning the nut on the draw bar clockwise.

-

When the rotor starts to turn in the stator, lift up on the special tool to remove the rotor.

-

-

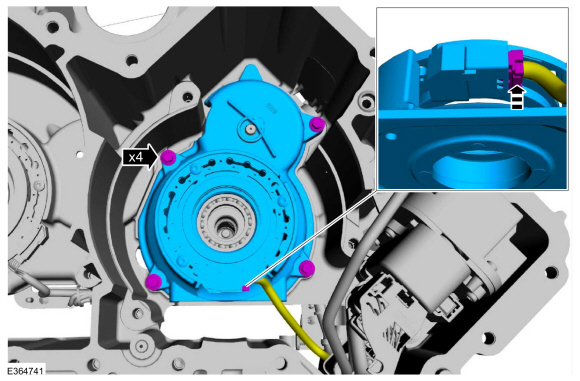

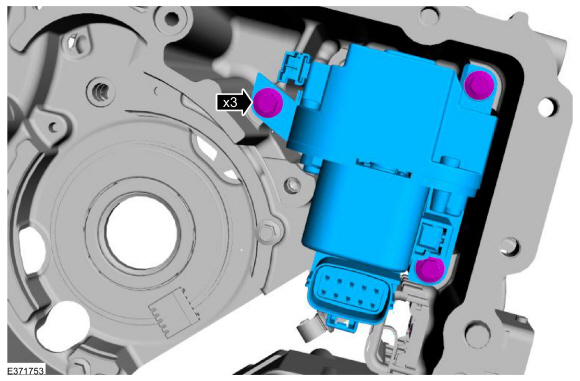

If equipped, cut and discard the tie strap.

-

Disconnect the park lock actuator.

-

NOTICE:

When removing the stator be careful not to bend or break the stator wires.

NOTICE:

After removing the stator, lay the stator on its side or damage to the windings may occur.

Remove the generator/starter stator.

-

Remove the planetary carrier support cover bolts, disconnect

the generator/starter resolver and remove the support cover.

-

Remove thrust washer from the planetary carrier support cover.

-

Remove the pump drive gear.

-

Remove the sun gear.

-

Remove the sun gear thrust bearing.

-

Remove the planetary carrier assembly.

-

NOTE:

Leave bearing inside ring gear.

Remove the ring gear.

-

NOTICE:

When removing the stator be careful not to bend or break the stator wires.

NOTICE:

After removing the stator, lay the stator on its side or damage to the windings may occur.

Rotate the transmission case on its side and remove the traction motor stator.

-

NOTE:

Only remove the traction motor resolver if it is necessary to clean debris from under the sensor.

Using a metal scriber, mark the traction motor resolver with

the transmission case as indicated for correct installation.

-

Remove the traction motor resolver bolts.

-

NOTE:

Lift up on the resolver and rotate to access the electrical connector.

Disconnect and remove the traction motor resolver.

-

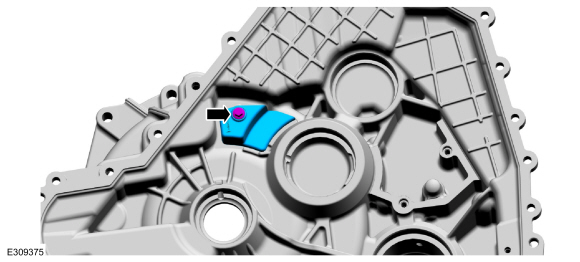

Disconnect the park lock actuator.

-

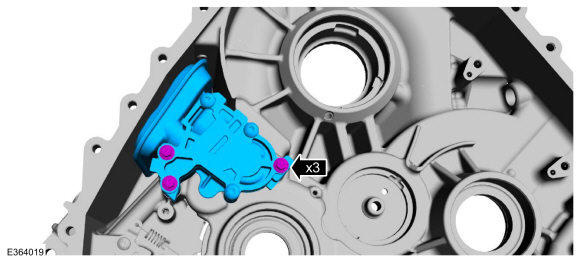

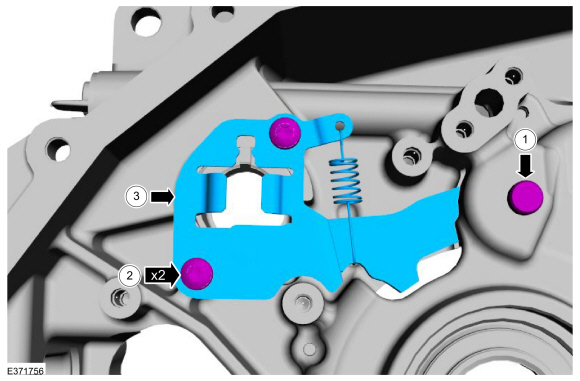

Remove the bolts and the park lock actuator.

-

Rotate the transmission case and position the case on blocks of wood.

-

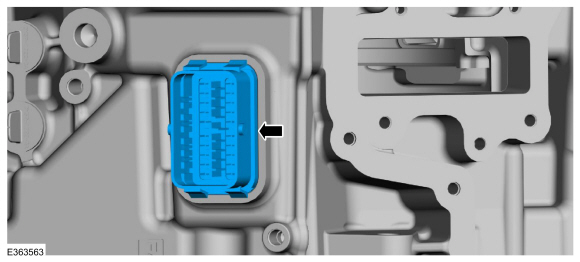

Remove the wiring harness bolts.

-

Remove the wiring harness bulkhead connector and the wiring harness from the transmission.

-

Inspect the wiring harness bulkhead seal for damage, replace if necessary.

-

Remove the bolts and the fluid pump and filter assembly.

-

-

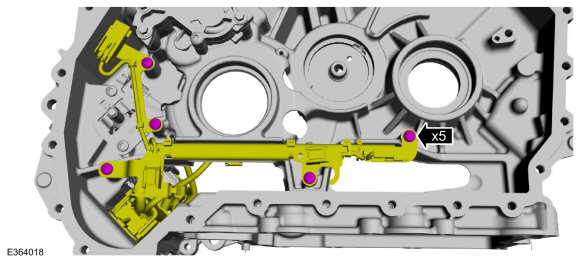

Remove the park pawl shaft.

-

Remove the park lock actuator guide bolts.

-

Remove the park lock actuator guide and park pawl.

NOTE:

The transmission cannot be removed from the vehicle separate

from the engine. Separate the transmission from the engine following the

additional steps in the transmission procedure...

Special Tool(s) /

General Equipment

204-069

(T81P-1104-C)

Remover/Installer, Front Wheel Hub

307-587Differential bearing installer and guideTKIT-2006UF-FLMTKIT-2006UF-ROW

307-791Install, Differential Bearing (AWD)

Hydraulic Press

Puller

DISASSEMBLY

Inspect the differential bearings for damage or excessive wear...

Other information:

Disconnect

WARNING:

Before beginning any service procedure in this

section, refer to Health and Safety Precautions in section 100-00

General Information. Failure to follow this instruction may result in

serious personal injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation)...

Acceptable Noise, Vibration and Harshness (NVH)

Noise is any undesirable sound, usually unpleasant in nature. Vibration

is any motion, shaking or trembling, that can be felt or seen when an

object moves back and forth or up and down. Harshness is a ride quality

issue where the vehicle's response to the road transmits sharply to the

customer...

Removal - Transmission

Removal - Transmission Disassembly and Assembly of Subassemblies - Differential

Disassembly and Assembly of Subassemblies - Differential