Lincoln Corsair: Fuel Charging and Controls - Turbocharger - 2.0L EcoBoost (177kW/240PS) – MI4 / Removal and Installation - Turbocharger Oil Supply Tube

Materials

| Name | Specification |

|---|---|

| Motorcraft® Metal Brake Parts Cleaner PM-4-A, PM-4-B, APM-4-C |

- |

Removal

NOTICE: The turbocharger compressor vanes can be damaged by even the smallest particles. When removing any turbocharger or engine air intake system component, ensure that no debris enters the system. Failure to do so may result in damage to the turbocharger.

NOTICE: Special attention needs to be given to the sealing ports for the oil feed, the oil drain, and the coolant lines, on turbocharged engines. The sealing ports must be totally clean and free from O-ring residue, have no damage to the sealing surface and the lines to ensure that there are no leaks or repeat repairs.

-

Remove the upper air cleaner outlet pipe.

Refer to: Air Cleaner Outlet Pipe (303-12A Intake Air Distribution and Filtering - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

-

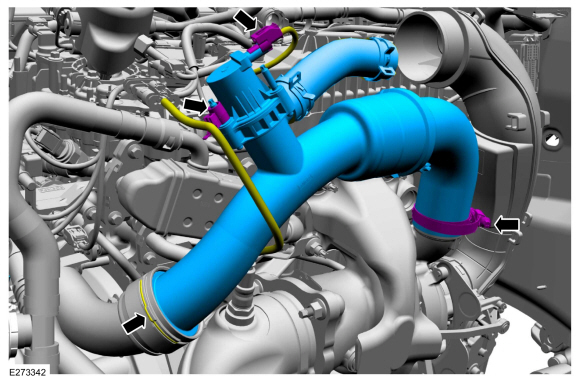

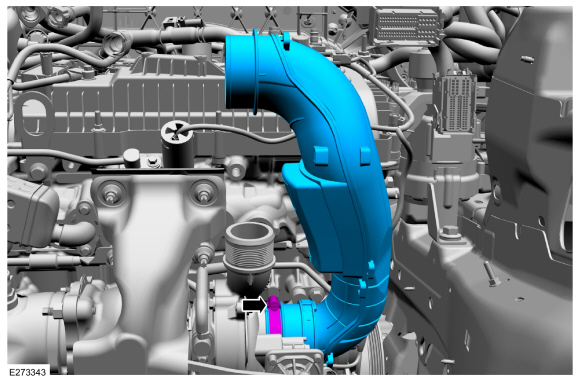

Disconnect the turbocharger bypass valve electrical

connector, then detach the harness retainer from the stud bolt. Release

the charge air cooler upper inlet pipe retaining clip. Loosen the charge

air cooler upper inlet pipe clamp, then remove the charge air cooler

upper inlet pipe.

|

-

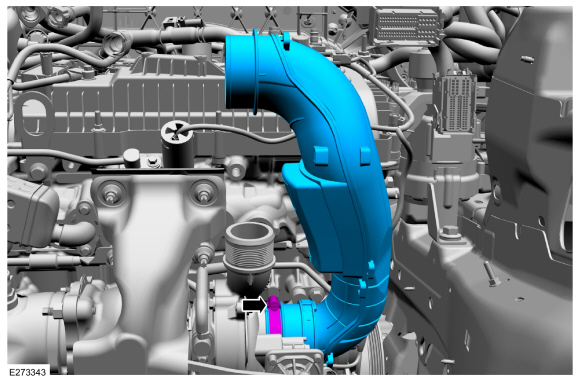

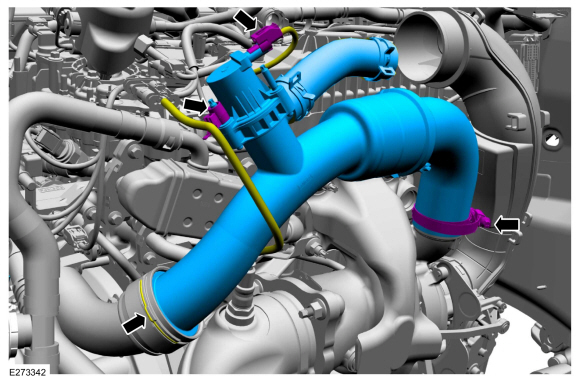

Loosen the lower air cleaner outlet pipe clamp, then remove the lower air cleaner outlet pipe.

|

-

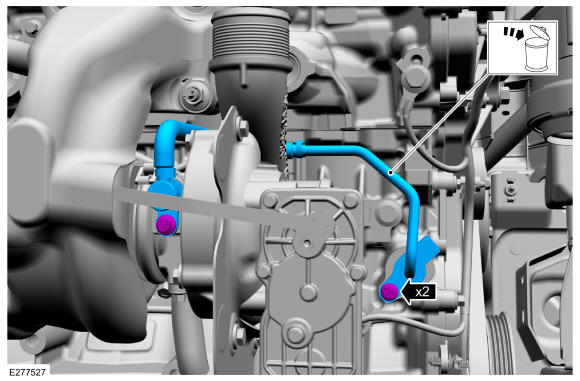

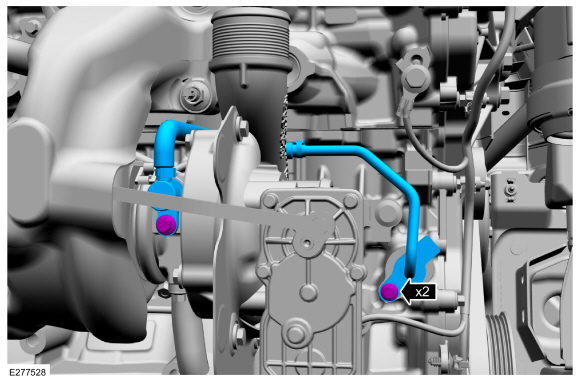

Remove the bolts, then remove and discard the

turbocharger oil supply tube.

|

Installation

-

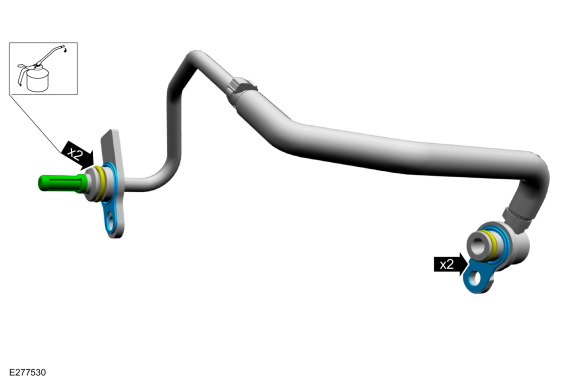

NOTICE: Do not reuse the turbocharger oil filter, a new turbocharger oil filter must be used.

NOTICE: Ensure that new turbocharger oil supply tube O-rings and gaskets are used.

Install the new turbocharger oil supply tube O-rings, gaskets and oil filter if not already installed. Lubricate the O-ring seals with clean engine oil.

Refer to: Specifications (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

|

-

NOTE: The oil supply tube must be fully seated prior to fastener tightening.

-

NOTICE: Do not use a metal brush, damage to sealing area will result in leaks.

Carefully use a nylon brush to remove the old O-ring residue, use brake cleaner to rinse the O-ring residue out of the turbocharger and engine O-ring bores. Inspect the area for deep scratches and gouges. Install new components if needed.

Material: Motorcraft® Metal Brake Parts Cleaner / PM-4-A, PM-4-B, APM-4-C

-

Install and fully seat the turbocharger oil supply tube, then install and tighten the bolts.

Torque: 97 lb.in (11 Nm)

-

|

-

Install the lower air cleaner outlet pipe, then tighten the lower air cleaner outlet pipe clamp.

Torque: 44 lb.in (5 Nm)

|

-

Install the charge air cooler upper inlet pipe, then

tighten the clamp. Engage the charge air cooler upper intake pipe

retaining clip. Attach the harness retainer to the stud bolt, then

connect the turbocharger bypass valve electrical connector.

Torque: 44 lb.in (5 Nm)

|

-

Install the upper air cleaner outlet pipe.

Refer to: Air Cleaner Outlet Pipe (303-12A Intake Air Distribution and Filtering - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

-

Check the engine oil level and fill as needed.

Refer to: Specifications (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

Removal and Installation - Turbocharger Oil Return Tube

Removal and Installation - Turbocharger Oil Return Tube

Materials

Name

Specification

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C

-

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Removal and Installation - Wastegate Control Actuator

Removal and Installation - Wastegate Control Actuator

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system...

Other information:

Lincoln Corsair 2020-2026 Service Manual: General Procedures - Charge Air Cooler (CAC) Cleaning

Materials Name Specification Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B, APM-4-C - Cleaning Remove the CAC . Refer to: Charge Air Cooler (CAC) (303-12A Intake Air Distribution and Filtering - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation)...

Lincoln Corsair 2020-2026 Service Manual: Removal and Installation - Rear Bumper Cover

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: Removal steps in this procedure may contain installation details. With the vehicle in NEUTRAL, position it on a hoist. Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation)...

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Programming the Garage Door Opener to Your Garage Door Opener Motor

- Interior Lamps

- Overhaul - Main Control Valve Body

- New on site

- Most important about car

USB Port

WARNING: Driving while distracted can result in loss of vehicle control, crash and injury. We strongly recommend that you use extreme caution when using any device that may take your focus off the road. Your primary responsibility is the safe operation of your vehicle. We recommend against the use of any hand-held device while driving and encourage the use of voice-operated systems when possible. Make sure you are aware of all applicable local laws that may affect the use of electronic devices while driving.

USB A