Lincoln Corsair: Rear Drive Axle/Differential / Removal and Installation - Axle Assembly

Special Tool(s) / General Equipment

| Transmission Jack | |

| Wooden Block |

Removal

NOTE: Removal steps in this procedure may contain installation instructions.

-

Remove the rear halfshafts.

Refer to: Rear Halfshaft (205-05 Rear Drive Halfshafts, Removal and Installation).

-

Remove the fuel tank.

Refer to: Fuel Tank (310-01A Fuel Tank and Lines - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

Refer to: Fuel Tank (310-01B Fuel Tank and Lines - 2.3L EcoBoost (199kW/270PS), Removal and Installation).

-

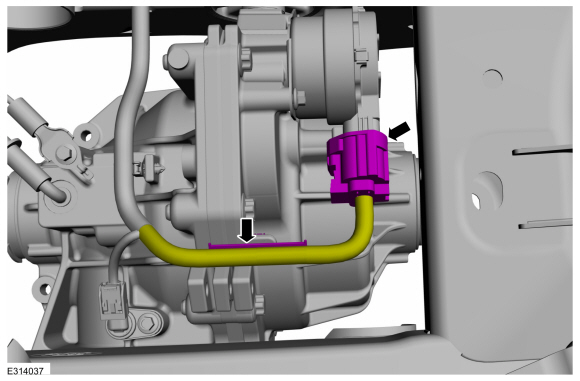

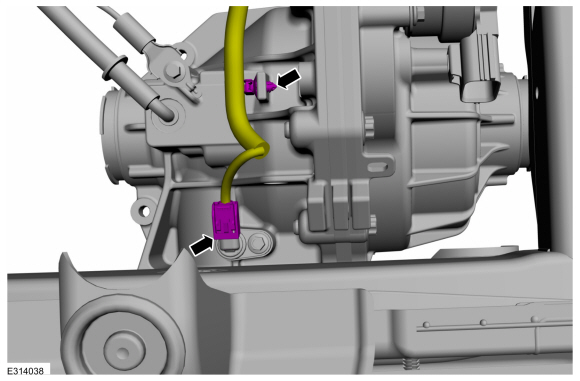

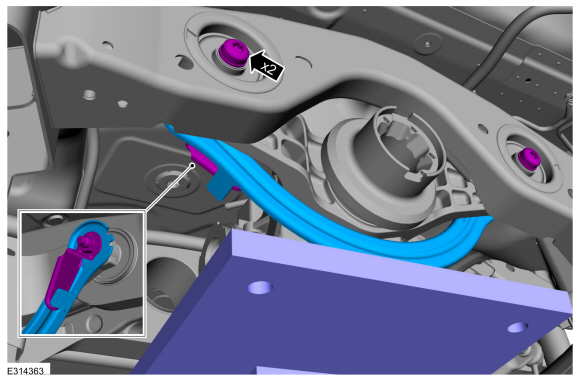

Disconnect the RDU actuator motor electrical connector and detach wiring harness retainer.

|

-

Disconnect the RDU speed sensor electrical connector and detach wiring harness retainer.

|

-

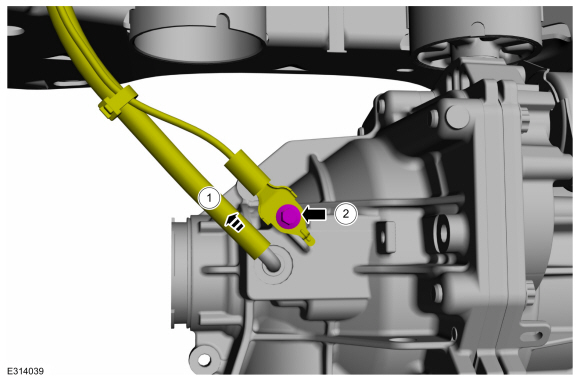

-

Remove the rear differential vent hose from RDU and position aside.

-

Remove the bolt and position the ground cable aside.

Torque: 106 lb.in (12 Nm)

-

Remove the rear differential vent hose from RDU and position aside.

|

-

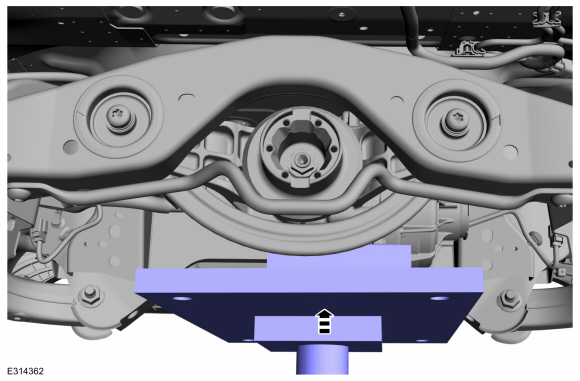

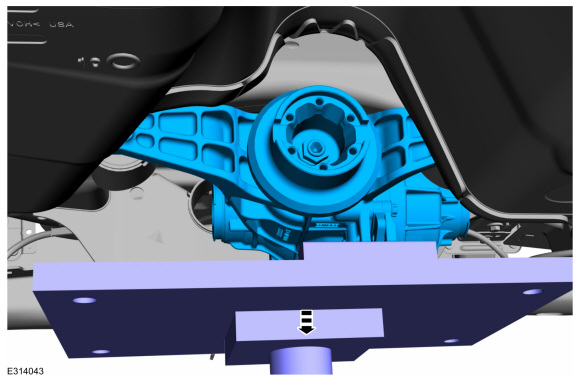

Position a transmission jack and wooden block to secure the RDU .

Use the General Equipment: Transmission Jack

Use the General Equipment: Wooden Block

|

-

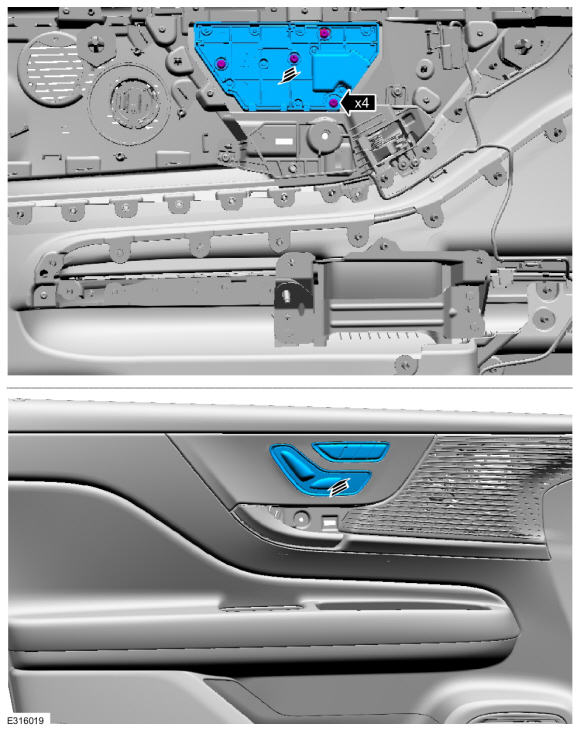

Remove the front RDU mounting bolts, nut and the protection shield.

Use the General Equipment: Transmission Jack

Use the General Equipment: Wooden Block

Torque: 76 lb.ft (103 Nm)

|

-

Remove the rear RDU mounting bolts.

Torque: 76 lb.ft (103 Nm)

|

-

Lower the transmission jack and remove the rear axle assembly.

Use the General Equipment: Transmission Jack

|

Installation

-

To install, reverse the removal procedure.

-

Check the differential fluid level.

Refer to: Differential Fluid Level Check (205-02 Rear Drive Axle/Differential, General Procedures).

-

NOTICE: If replacing the axle assembly, the AWD control module will need to be reconfigured with the new RDU bar code information. If the new bar code information does not match the existing AWD control module information, driveline damage or driveability concerns can occur.

NOTE: Using the diagnostic scan tool, carry out the rear drive unit calibration routine.

NOTE: The 16/17 -digit alpha numeric bar code is located on the label attached to the RDU . Using the scan tool, configure RDU bar code to AWD module through the OBD port.

General Procedures - Differential Fluid Level Check

General Procedures - Differential Fluid Level Check

Check

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation)...

Removal and Installation - Drive Pinion Flange

Removal and Installation - Drive Pinion Flange

Special Tool(s) /

General Equipment

205-126

(T78P-4851-A)

Holding Fixture, Drive Pinion Flange

205-233

(T85T-4851-AH)

Installer, Drive Pinion FlangeTKIT-1985-FH-1

303-249Remover, Crankshaft Timing Pulley

Flat-Bladed Screwdriver

Materials

Name

Specification

Motorcraft® Premium Long-Life GreaseXG-1-E1

ESA-M1C75-B

Removal

Remov..

Other information:

Lincoln Corsair 2020-2026 Service Manual: Specifications

Reference Value Symptom Chart NOTE: The Reference Value Symptom Chart provides guidance in selecting the appropriate parameter identification (PID) or measured signal related to the fault area. Select a symptom from the symptom chart along with the category number and go to the PID/Measured Signal Chart. For multiple symptoms, select the symptom that is the most evident. ..

Lincoln Corsair 2020-2026 Service Manual: Diagnosis and Testing - Rear Electric Drive Assembly

Diagnostic Trouble Code (DTC) Chart Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Module DTC Description Action APIM U0136:00 Lost Communication With Differential Control Module - Rear: No Sub Type Information GO to Pinpoint Test BE..

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Capacities and Specifications - 2.0L

- Auto Hold (IF EQUIPPED)

- Overhaul - Main Control Valve Body

- New on site

- Most important about car

360 Degree Camera Cameras

Locating the Rear View Camera

The rear view camera is on the tailgate.

Locating the Front View Camera