Lincoln Corsair: Rear Suspension / Removal and Installation - Upper Arm

Special Tool(s) / General Equipment

| Vehicle/Axle Stands |

Removal

NOTE: Removal steps in this procedure may contain installation details.

-

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

NOTICE: Make sure that the insulator pads are correctly positioned to prevent direct contact with other components.

Raise the suspension to curb height.

Use the General Equipment: Vehicle/Axle Stands

|

-

NOTICE: Tighten the suspension fasteners with the weight of the vehicle on the wheels and tires or use a suitable jack to raise the suspension to curb height or damage to the bushings may occur.

NOTE: Only tighten the nuts and bolts when the suspension is in the normal drive position.

-

NOTE: Make sure that a new bolt is installed.

Remove and discard the upper arm-to-wheel knuckle bolt.

Torque:

Stage 1: 98 lb.ft (133 Nm)

Stage 2: 120°

-

NOTE: Make sure that the new bolt and nut are installed.

Remove and discard the upper arm-to-frame bolt and nut.

Torque:

Stage 1: 159 lb.in (18 Nm)

Stage 2: 98 lb.ft (133 Nm)

Stage 3: 90°

-

Remove the upper arm.

-

|

Installation

-

To install, reverse the removal procedure.

-

Check and if necessary adjust rear camber.

Refer to: Rear Camber Adjustment (204-00 Suspension System - General Information, General Procedures).

Removal and Installation - Toe Link

Removal and Installation - Toe Link

Special Tool(s) /

General Equipment

Vehicle/Axle Stands

Removal

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation)...

Removal and Installation - Wheel Bearing and Wheel Hub - AWD

Removal and Installation - Wheel Bearing and Wheel Hub - AWD

Special Tool(s) /

General Equipment

205-D070

(D93P-1175-B)

Remover, Front Wheel Hub

Removal

Remove the rear wheel speed sensor...

Other information:

Lincoln Corsair 2020-2026 Owners Manual: What Is the 360 Degree Camera. 360 Degree Camera Precautions. 360 Degree Camera Limitations

What Is the 360 Degree Camera The 360 degree camera system consists of front, side and rear cameras. The 360 degree camera system: Allows you to see what is directly in front of or behind your vehicle. Provides a cross traffic view in front of and behind your vehicle...

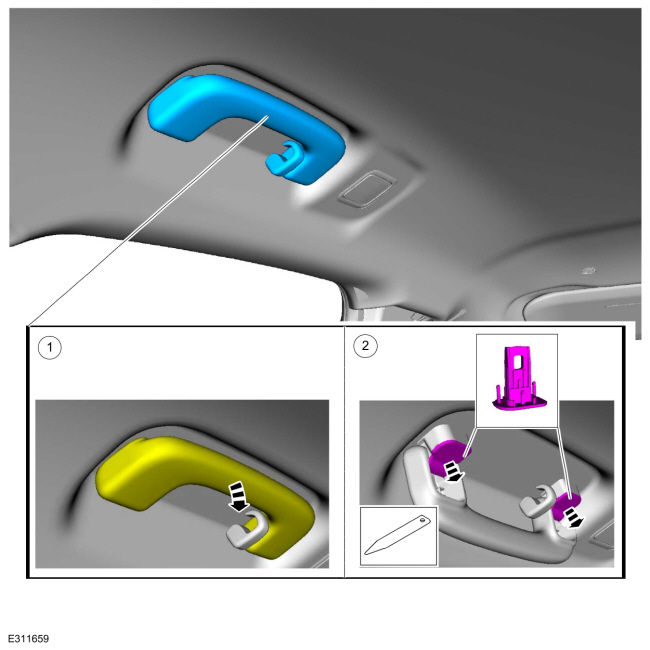

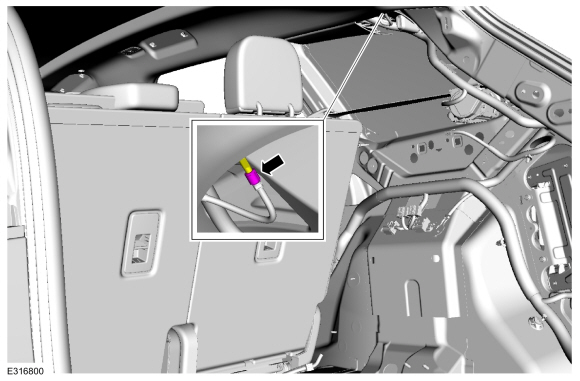

Lincoln Corsair 2020-2026 Service Manual: Removal and Installation - Gear Shift Module (GSM)

Special Tool(s) / General Equipment Interior Trim Remover Removal Remove the FCIMB . Refer to: Front Controls Interface Module B (FCIMB) (415-00 Information and Entertainment System - General Information, Removal and Installation)...

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Auto-Start-Stop

- Programming the Garage Door Opener to Your Garage Door Opener Motor

- Memory Function

- New on site

- Most important about car

Adjusting the Steering Wheel - Vehicles With: Power Adjustable Steering Column

WARNING: Do not adjust the steering wheel when your vehicle is moving.

Note: Make sure that you are sitting in the correct position.