Lincoln Corsair: Engine - 2.0L EcoBoost (177kW/240PS) – MI4 / General Procedures - Valve Clearance Adjustment

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

-

Remove the valve cover.

Refer to: Valve Cover (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

-

Remove the RH front fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

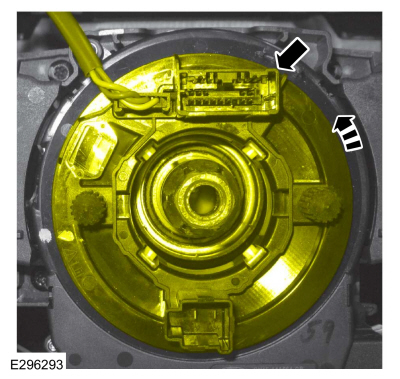

NOTE: Turn the engine clockwise only, and only use the crankshaft bolt.

NOTE: Measure the clearance of each valve at base circle, with the lobe pointed away from the tappet.

Use a feeler gauge to measure the clearance of each valve and record its location.

Use the General Equipment: Feeler Gauge

|

-

Valve tappet assembly grade chart

-

Grade

-

Id Mark

-

Thickness (mm)

-

Grade

|

-

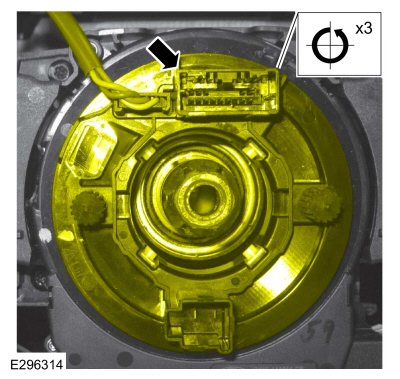

NOTE: There are two numbers on the valve tappet, one is date code and the other is valve tappet thickness.

NOTE: The date code “R0605” represents the year made (R), the month (06) and the day (05).

NOTE: A tappet with the number N650 has the thickness of 3.650 mm.

NOTE: Select tappets using this formula: tappet thickness = measured clearance + the existing tappet thickness - nominal clearance.

NOTE: The nominal clearance is:

- intake: 0.25 mm (0.0095 in).

- exhaust: 0.36 mm (0.0142 in).

NOTE: The acceptable clearances after being fully installed are:

- intake: 0.19-0.31 mm (0.0075-0.0122 in).

- exhaust: 0.30-0.42 mm (0.0118-0.0165 in).

-

If any tappets do not measure within specifications, install new tappets in these locations.

Adjustment

-

NOTE: The following step is only necessary if adjustment is required.

Remove the camshafts.

Refer to: Camshafts (303-01A Engine - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

General Procedures - Engine Oil Draining and Filling

General Procedures - Engine Oil Draining and Filling

Special Tool(s) /

General Equipment

Oil Drain Equipment

Draining

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation)...

Removal and Installation - Camshafts

Removal and Installation - Camshafts

Special Tool(s) /

General Equipment

303-1685Alignment Tool, Camshaft

303-507Timing Peg, Crankshaft TDCTKIT-2001N-FLMTKIT-2001N-ROW

Feeler Gauge

Removal

NOTE:

During engine repair procedures, cleanliness is extremely

important...

Other information:

Lincoln Corsair 2020-2026 Owners Manual: Engine Oil Dipstick. Engine Oil Check. Oil Change Indicator Reset

Engine Oil Dipstick Minimum. Nominal. Maximum. Engine Oil Check WARNING: Do not work on a hot engine. To check the engine oil level consistently and accurately, do the following: Make sure the parking brake is on. Make sure the transmission is in park (P) or neutral (N)...

Lincoln Corsair 2020-2026 Service Manual: Removal and Installation - Exterior Mirror

Special Tool(s) / General Equipment Flat Headed Screw Driver Removal NOTE: Removal steps in this procedure may contain installation details. Exterior mirror assembly Remove the front door trim panel. Refer to: Front Door Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation)...

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Programming the Garage Door Opener to Your Hand-Held Transmitter

- Exterior Mirrors

- Child Safety Locks

- New on site

- Most important about car

Selecting a Drive Mode. DRIVE MODES

Selecting a Drive Mode

Note: Drive mode changes may not be available when the ignition is off.