Lincoln Corsair: Transmission Cooling - Automatic Transmission – HF45 / General Procedures - Transmission Fluid Cooler - Backflushing and Cleaning - Plug-In Hybrid Electric Vehicle (PHEV)

Lincoln Corsair 2020-2024 Service Manual / Powertrain / Automatic Transmission / Transmission Cooling - Automatic Transmission – HF45 / General Procedures - Transmission Fluid Cooler - Backflushing and Cleaning - Plug-In Hybrid Electric Vehicle (PHEV)

Special Tool(s) / General Equipment

| Transmission Cooling System Heated Flusher |

Materials

| Name | Specification |

|---|---|

| Motorcraft® MERCON® ULV Automatic Transmission Fluid XT-12-QULV |

WSS-M2C949-A, MERCON® ULV |

Activation

-

NOTE: Use transmission fluid specified for this transmission. Do not use any supplemental transmission fluid additives or cleaning agents. The use of these products could cause internal transmission components to fail, which will affect the operation of the transmission.

The transmission cooling system (cooler and lines) MUST be flushed every time the transmission is overhauled or replaced in order to minimize the likelihood of repeat repairs. It is mandatory that proper equipment and procedures be followed when flushing coolers/lines. The flushing equipment used MUST:

-

maintain fluid at 60°C (140°F) or above,

-

pulsate fluid during cleaning,

-

have a GPM flow meter,

-

have twin magnetic filters,

-

and have air purge capability before and after flushing.

-

maintain fluid at 60°C (140°F) or above,

-

If equipment meeting the specifications above is not

available, the transmission fluid cooler(s) should be replaced and the

lines cleaned by hand.

-

Check and top off fluid level of the transmission cooling system heated flusher with transmission fluid.

Use the General Equipment: Transmission Cooling System Heated Flusher

Material: Motorcraft® MERCON® ULV Automatic Transmission Fluid / XT-12-QULV (WSS-M2C949-A, ) (MERCON® ULV)

-

Turn on the heater and allow the fluid in the cooler

line flusher 15-30 minutes to heat up to 60°C (140°F) before using.

-

Install the line adapters on the transmission fluid cooler tube.

-

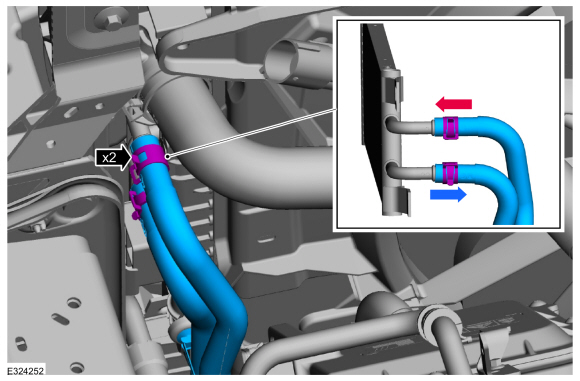

Attach the cooler line flusher red line to the transmission fluid cooler inlet tube assembly.

|

-

Attach the cooler line flusher blue line to the transmission fluid cooler outlet tube assembly.

-

Follow the equipment instructions to purge the

transmission fluid cooler tubes and transmission fluid cooler prior to

starting the flushing procedure.

-

Allow the transmission fluid cooling system to backflush

for 10-15 minutes, then flush the transmission fluid cooler in a normal

flow direction for an additional 10-15 minutes.

-

If the transmission fluid cooling system heated flusher is equipped with an inspection micron filter:

-

Remove and clean the Oberg 28 micron filter.

-

Install the filter.

-

Backflush the system for 5 minutes.

-

Remove and inspect the filter.

-

If debris/contamination is present on the filter, repeat step 9.

-

Remove and clean the Oberg 28 micron filter.

-

Follow the equipment instructions to purge the transmission fluid cooler.

-

Clean the transmission fluid cooler tubes by hand.

Diagnosis and Testing - Transmission Cooling

Diagnosis and Testing - Transmission Cooling

Principles of Operation

Inspection and Verification

Verify the customer concern by operating the vehicle to duplicate the condition.

If the inspection reveals an obvious concern(s) that can be readily identified, repair as necessary...

Removal and Installation - Transmission Fluid Cooler

Removal and Installation - Transmission Fluid Cooler

Removal

Remove the A/C condenser.

Refer to: Transmission Fluid Cooler Tubes (307-02A Transmission Cooling

- 8-Speed Automatic Transmission – 8F35/8F40, Removal and

Installation)...

Other information:

Lincoln Corsair 2020-2024 Service Manual: Removal and Installation - Rear Stabilizer Bar

Removal With the vehicle in NEUTRAL, position it on a hoist. Refer to: Jacking and Lifting (100-02 Jacking and Lifting) . NOTICE: Do not use power tools to remove or install the stabilizer bar link nuts. Damage to the stabilizer bar link ball joints and boots may occur...

Lincoln Corsair 2020-2024 Service Manual: Removal and Installation - Power Transfer Unit Input Shaft Seal RH

Special Tool(s) / General Equipment 100-001 (T50T-100-A) Slide Hammer 205-153 (T80T-4000-W) Handle 308-777Remover and Installer, PTU Input Shaft Seal 308-970Installer, RH halfshaft Seal 308-973Remover, PTU Input Sleeve Removal With the vehicle in NEUTRAL, position it on a hoist...

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Memory Function

- Auto Hold (IF EQUIPPED)

- Capacities and Specifications - 2.0L

- New on site

- Most important about car

Information on P Type Tires

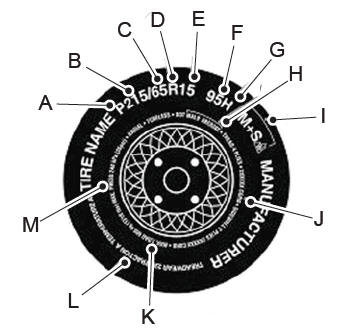

P215/65R15 95H is an example of a tire size, load index and speed rating. The definitions of these items are listed below. (Note that the tire size, load index and speed rating for your vehicle may be different from this example.)

P: Indicates a tire, designated by the Tire and Rim Association, that may be used for service on cars, sport utility vehicles, minivans and light trucks. Note: If your tire size does not begin with a letter this may mean it is designated by either the European Tire and Rim Technical Organization or the Japan Tire Manufacturing Association. 215: Indicates the nominal width of the tire in millimeters from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire. 65: Indicates the aspect ratio which gives the tire's ratio of height to width. R: Indicates a radial type tire. 15: Indicates the wheel or rim diameter in inches. If you change your wheel size, you will have to purchase new tires to match the new wheel diameter. 95: Indicates the tire's load index. It is an index that relates to how much weight a tire can carry. You may find this information in your owner’s manual. If not, contact a local tire dealer.Copyright © 2024 www.licorsair.com