Lincoln Corsair: Driveshaft / General Procedures - Driveshaft Angle Measurement

Check

NOTE: Prior to checking driveline angularity, inspect the U-joints for correct operation.

NOTE: An incorrect driveline angle can cause a vibration or shudder.

NOTE: Driveline angularity is the angular relationship between the engine crankshaft, the driveshaft and the rear axle pinion. Factors determining driveline angularity include ride height, rear spring and engine mounts.

-

NOTE:

- Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402. Carry out the following preliminary setup steps:

-

Inspect the U-joint for correct operation.

-

Park the vehicle on a level surface such as a drive-on hoist or back onto a front end alignment rack.

-

Calibrate the Anglemaster II Driveline

Inclinometer/Protractor by placing it on a clean, flat level section of

the frame rail and press the ALT-ZERO button.

-

Calibrate the anglemaster by placing it on the bottom of the transfer case and press the ALT-ZERO button.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

|

-

Measure the slope of the rear driveshaft front tube. The measured angle will be the front joint operating angle.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

|

-

Calibrate the anglemaster by placing it on the clean,

flat surface of the rear driveshaft front tube and press the ALT-ZERO

button.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

|

-

NOTE: Rotate the driveshaft until the flange U-joint cup is parallel with the floor. This will simplify taking measurements.

Measure the slope of the rear driveshaft rear tube. The measured angle will be the center joint operating angle.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

|

-

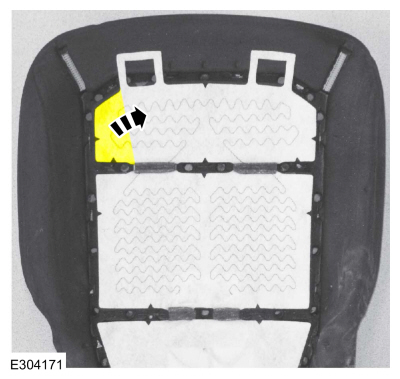

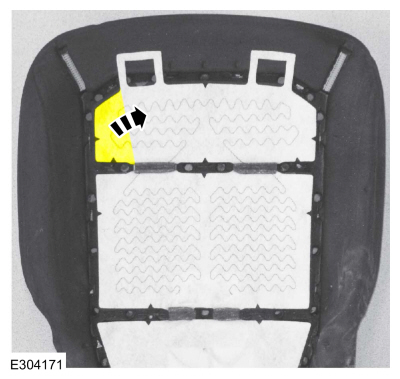

Calibrate the anglemaster by placing it on the clean,

flat locator surface on the left side of the drive axle and press the

ALT-ZERO button.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

|

-

Measure the slope of the rear driveshaft rear tube. The measured angle will be the rear joint operating angle.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

|

-

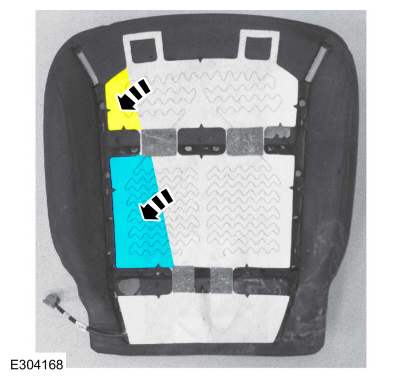

NOTE: Repeat this step for each center support bearing on the driveshaft.

NOTE: It is not necessary to remove the U-joint snap ring, if equipped, for these measurements.

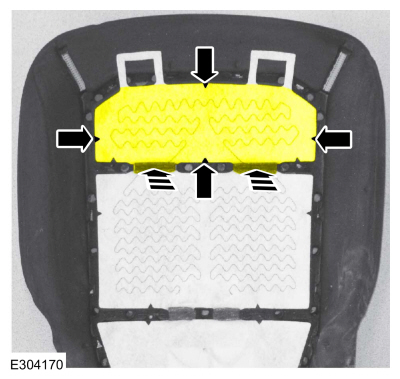

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402. Measure the slope of the components in front and behind the center support bearing U-joint in the area indicated. Record the front component as angle A and the rear component as angle B.

|

-

NOTE: When 2 connected components slope in the same direction, subtract the smallest number from the larger number to find the U-joint operating angle. When 2 connected components slope in the opposite direction, add the measurements to find the U-joint operating angle.

Calculate the difference in the slope of the components to determine the U-joint operating angle.

-

NOTE:

- The U-joint operating angle is the angle formed by 2 yokes connected by a cross and bearing kit. Ideally, the operating angles on each connection of the driveshaft must:

-

be equal or within one degree of each other.

-

have a 3 degree maximum operating angle.

-

have at least one-half of one degree continuous operating angle.

-

If the angle is not within specifications, repair or

adjust to obtain the correct angle. Inspect the engine mounts,

transmission mounts, center support bearing mounting, rear suspension,

rear axle, rear axle mounting or the frame for wear or damage.

Diagnosis and Testing - Driveshaft

Diagnosis and Testing - Driveshaft

Symptom Chart(s)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

General Procedures - Driveshaft Runout and Balancing

General Procedures - Driveshaft Runout and Balancing

Special Tool(s) /

General Equipment

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

Inspection

NOTE:

Driveline vibration exhibits a higher frequency and lower

amplitude then high-speed shake...

Other information:

Lincoln Corsair 2020-2026 Owners Manual: Passive Key

Note: You may not be able to shift out of park (P) unless the passive key is inside your vehicle. Your remote control operates the power locks, remote start system, and liftgate. Your remote control must be in your vehicle to activate the push button start...

Lincoln Corsair 2020-2026 Owners Manual: Mechanical Key

The intelligent access key also contains a removable key blade that you can use to lock and unlock your vehicle. Turn the top of the key toward the front of your vehicle once to lock all doors. Turn the top of the key toward the rear of your vehicle once to unlock the driver door only...

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Interior Lamps

- Fuel Quality - Gasoline

- Memory Function

- New on site

- Most important about car

Second Stage: Checking Tire Pressure

WARNING: If the tire does not inflate to the recommended tire pressure within 15 minutes, stop and call roadside assistance.

WARNING: The power plug may get hot after use and should be handled carefully when unplugging.

Check the air pressure of your tires as follows: