Lincoln Corsair: Engine System - General Information / General Procedures - Cylinder Block Distortion

Lincoln Corsair 2020-2026 Service Manual / Powertrain / Engine / Engine System - General Information / General Procedures - Cylinder Block Distortion

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

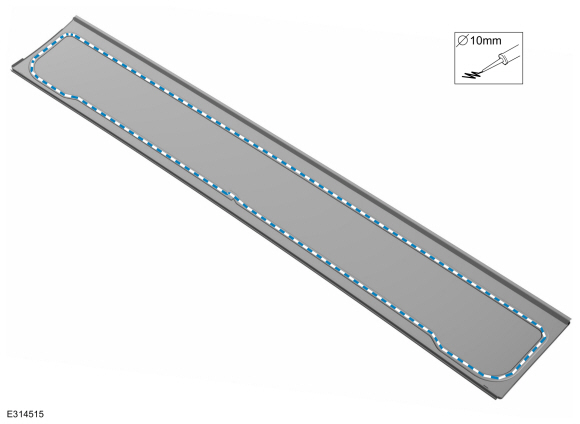

Use a Straightedge and a Feeler Gauge Set to inspect the cylinder block for flatness.

Use the General Equipment: Feeler Gauge

|

General Procedures - Cylinder Block Core Plug Replacement

General Procedures - Cylinder Block Core Plug Replacement

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

Materials

Name

Specification

Motorcraft® Threadlock and SealerTA-25-B

-

Repair

All core plugs

NOTE:

Cylinder block core plug shown, cylinder head core plug similar...

General Procedures - Cylinder Bore Taper

General Procedures - Cylinder Bore Taper

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated...

Other information:

Lincoln Corsair 2020-2026 Service Manual: Description and Operation - Front Seats - System Operation and Component Description

System Operation System Diagram - Driver Memory Seat Item Description 1 HS-CAN1 2 PCM 3 BCM 4 HS-CAN1 5 Ignition Switch 6 GWM 7 Memory Set Switch 8 MS-CAN 9 DSM 10 MS-CAN 11 DDM 12 Memory Power Seat Motors 13 LIN 14 Driver Seat Control Switch ..

Lincoln Corsair 2020-2026 Service Manual: Removal and Installation - Front Seatbelt Retractor and Pretensioner

Removal WARNING: The following procedure prescribes critical repair steps required for correct restraint system operation during a crash. Follow all notes and steps carefully. Failure to follow step instructions may result in incorrect operation of the restraint system and increases the risk of serious personal injury or death in a crash. NOTE: Removal steps in this procedure ..

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Technical Specifications

- Refueling - Gasoline

- Programming the Garage Door Opener to Your Garage Door Opener Motor

- New on site

- Most important about car

Adjusting the Steering Wheel - Vehicles With: Power Adjustable Steering Column

WARNING: Do not adjust the steering wheel when your vehicle is moving.

Note: Make sure that you are sitting in the correct position.

Copyright © 2026 www.licorsair.com