Lincoln Corsair: Driveshaft / Removal and Installation - Rear Driveshaft

Special Tool(s) /

General Equipment

| Flat Headed Screw Driver |

| Punch |

| Copper Hammer |

Removal

-

Remove the muffler and tailpipe.

Refer to: Muffler and Tailpipe (309-00B Exhaust System - 2.3L EcoBoost (199kW/270PS), Removal and Installation).

Refer to: Muffler and Tailpipe (309-00A Exhaust System - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

-

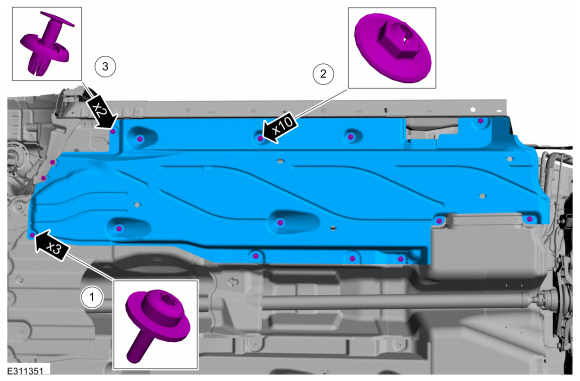

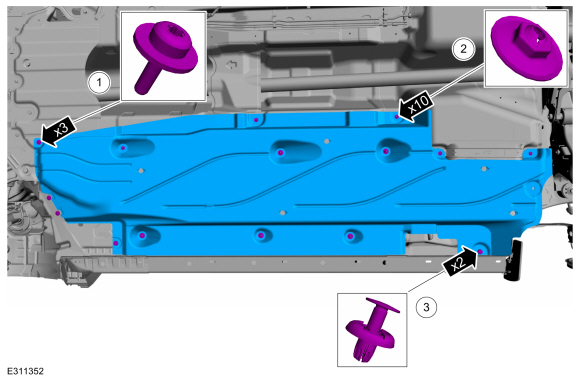

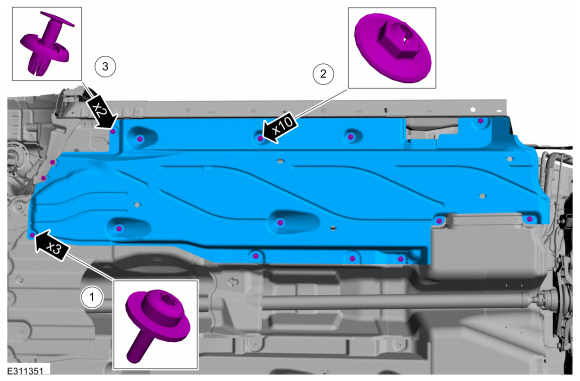

Remove the LH front air deflector.

-

Remove the screws and washers.

-

Remove the stamped nuts.

-

Remove the push pins.

-

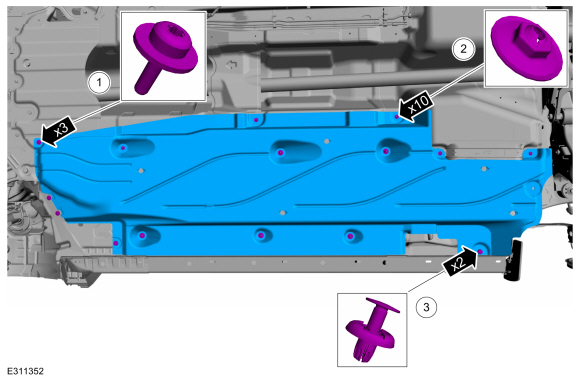

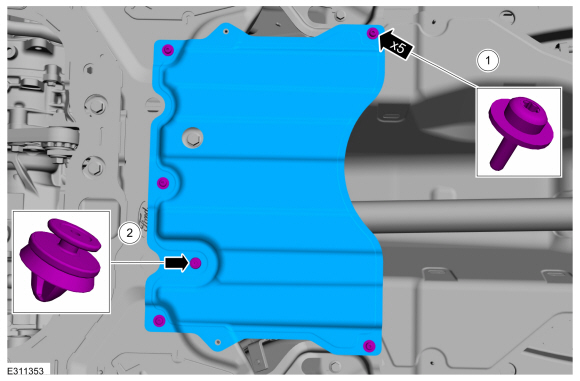

Remove the RH front air deflector.

-

Remove the screws and washers.

-

Remove the stamped nuts.

-

Remove the push pins.

-

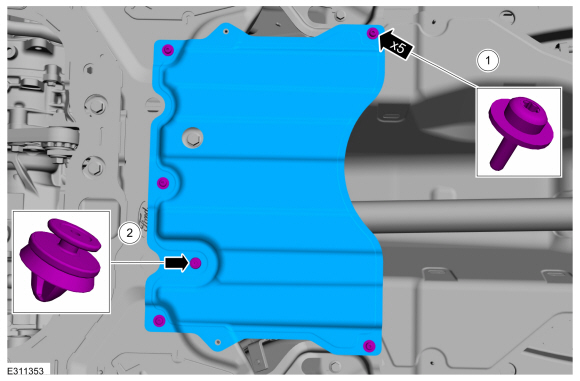

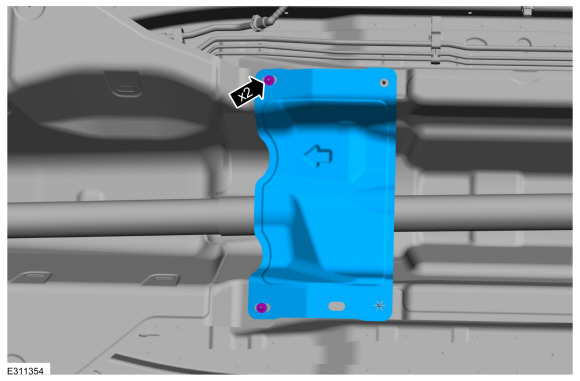

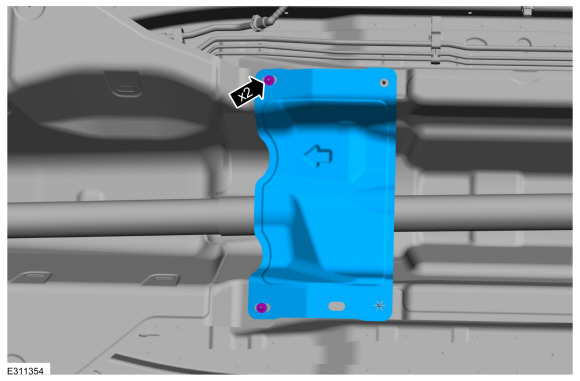

Remove the heat shield.

-

Remove the screws and washers.

-

Remove the push pin.

-

Remove the stamped nuts and the heat shield.

-

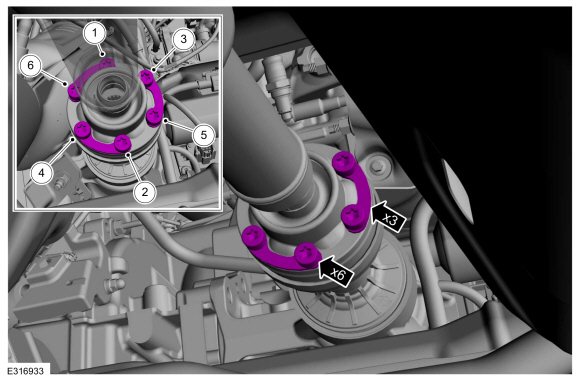

NOTE:

The installation step requires the aid of another technician.

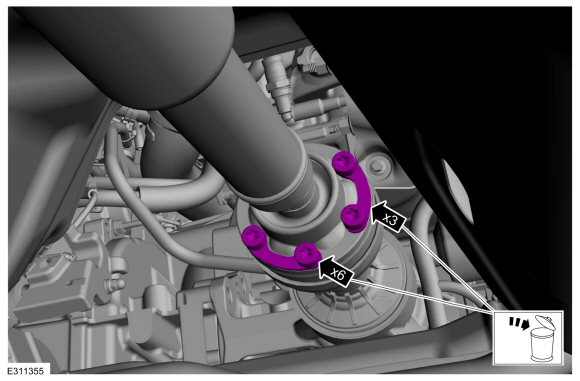

Remove and discard the driveshaft to PTU bolts and the retaining straps.

-

Separate the driveshaft from the PTU flange.

-

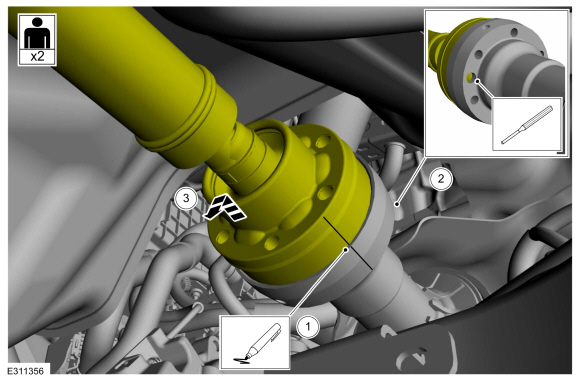

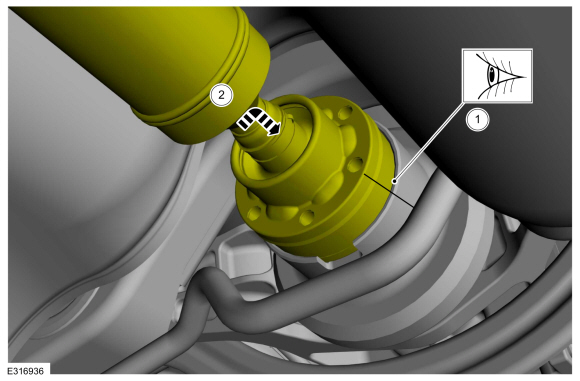

NOTE:

Make sure that the component aligns with the installation mark.

Index-mark the driveshaft and PTU flange.

-

NOTICE:

Do not remove driveshaft from the PTU flange by

pulling on the driveshaft tube. Damage to the CV-joint can result.

NOTE:

This is a tight fit, do not remove the CV flange from the PTU flange at this time.

Using general equipments, separate the driveshaft from the PTU flange.

Use the General Equipment: Punch

Use the General Equipment: Copper Hammer

-

NOTE:

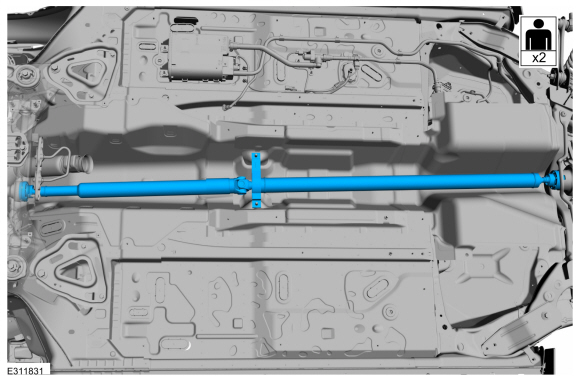

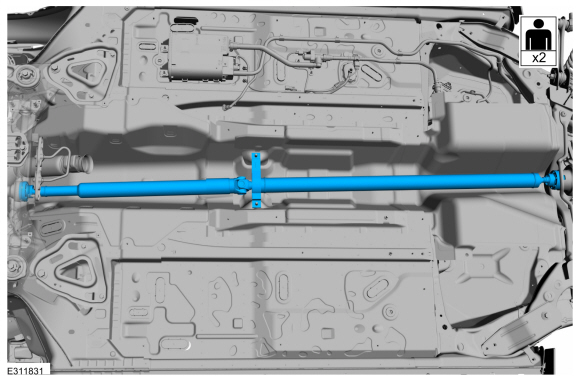

This step requires the aid of another technician.

Remove the driveshaft from the PTU flange.

-

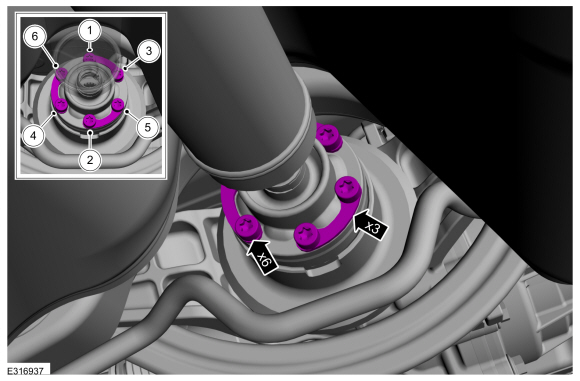

Remove and discard the driveshaft to RDU flange bolts and retaining straps.

-

Separate the driveshaft from the drive pinion flange.

-

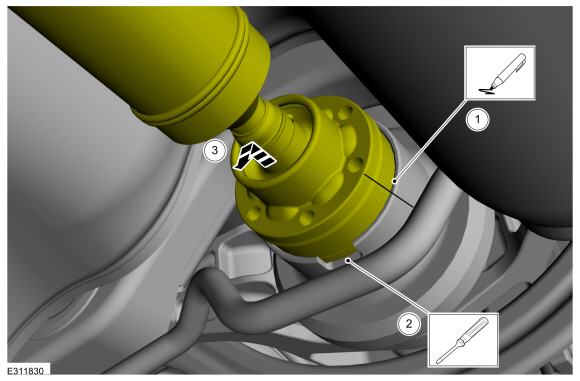

NOTE:

Make sure that the component aligns with the installation mark.

Index-mark the driveshaft and RDU flange.

-

Using general equipment, separate the driveshaft from drive pinion flange.

Use the General Equipment: Flat Headed Screw Driver

-

Remove the driveshaft from the RDU flange.

-

Remove the center bearing nuts.

-

NOTE:

Do not allow the angle of the driveshaft U-joint exceed 5 degrees.

NOTE:

This step requires the aid of another technician.

With the help of an assistant, remove the driveshaft.

Installation

-

NOTE:

This step requires the aid of another technician.

With the help of an assistant, install the driveshaft.

-

Install the center bearing nuts.

Torque:

41 lb.ft (55 Nm)

-

-

Align the index-mark on the driveshaft and RDU flange.

-

Fit the driveshaft into the RDU flange.

-

-

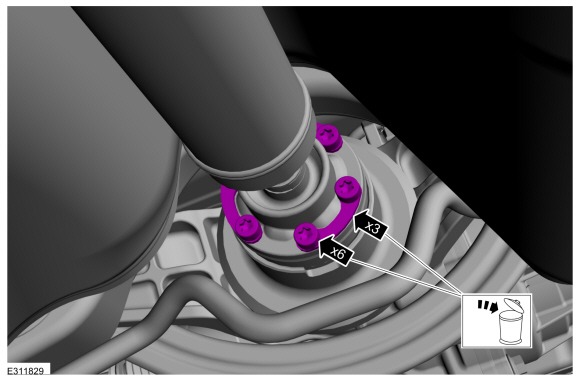

Install the new driveshaft to the RDU flange retaining straps and bolts.

-

Tighten the driveshaft to the RDU flange bolts in criss-cross pattern.

Torque:

26 lb.ft (35 Nm)

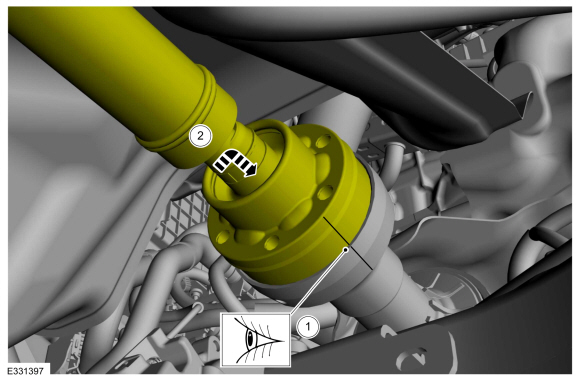

-

-

Align the index-mark on the driveshaft and PTU flange.

-

Fit the driveshaft into the drive pinion flange.

-

-

Install the new driveshaft to the PTU flange retaining straps and bolts.

-

Tighten the driveshaft to the PTU flange bolts in criss-cross pattern.

Torque:

26 lb.ft (35 Nm)

-

Install the heat shield and the stamped nuts.

-

Install the heat shield.

-

Install the screws and washers.

-

Install the push pin.

-

Install the RH front air deflector.

-

Install the screws and washers.

-

Install the stamped nuts.

-

Install the push pins.

-

Install the LH front air deflector.

-

Install the screws and washers.

-

Install the stamped nuts.

-

Install the push pins.

-

Install the muffler and tailpipe.

Refer to: Muffler and Tailpipe (309-00B Exhaust System - 2.3L EcoBoost (199kW/270PS), Removal and Installation).

Refer to: Muffler and Tailpipe (309-00A Exhaust System - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

Special Tool(s) /

General Equipment

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

Inspection

NOTE:

Driveline vibration exhibits a higher frequency and lower

amplitude then high-speed shake...

Other information:

Audio source. Select to choose a

different audio source.

Presets. Swipe left to view more

presets.

You can access these options using the

touchscreen or voice commands.

Sources

Press this button to select the source of

media you want to listen to.

AM/FM Radio

Tuning a Station

You can use the tune or seek controls on the

radio bezel to select a station.

To tune a station using the tou..

Materials

Name

Specification

Motorcraft® Disconnect Rear Drive Unit FluidXY-75W-QL

-

Removal

NOTE:

Removal steps in this procedure may contain installation details.

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

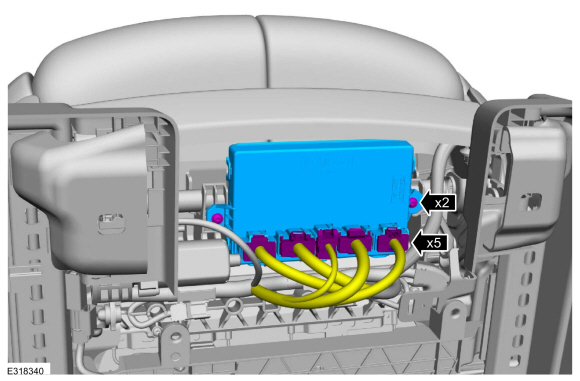

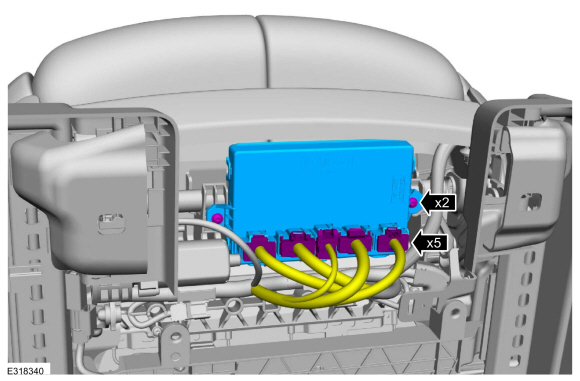

Disconnect RDU speed sensor..

General Procedures - Driveshaft Runout and Balancing

General Procedures - Driveshaft Runout and Balancing