Lincoln Corsair: Power Transfer Unit - 2.0L EcoBoost (177kW/240PS) – MI4 / General Procedures - Power Transfer Unit Draining and Filling

Lincoln Corsair 2020-2026 Service Manual / Powertrain / Automatic Transmission / Power Transfer Unit - 2.0L EcoBoost (177kW/240PS) – MI4 / General Procedures - Power Transfer Unit Draining and Filling

Materials

| Name | Specification |

|---|---|

| Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear Lubricant XY-75W85-QL |

WSS-M2C942-A |

Draining

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Remove the underbody shield.

Refer to: Engine Front Undershield (501-02 Front End Body Panels, Removal and Installation).

-

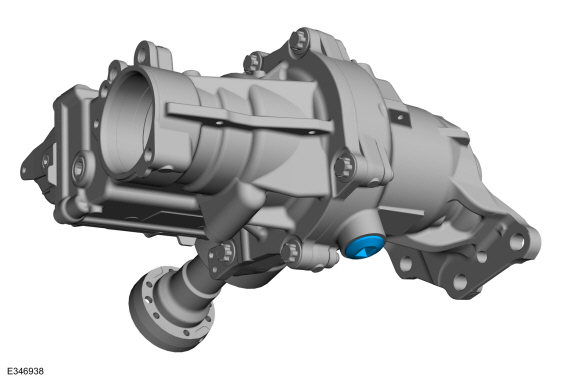

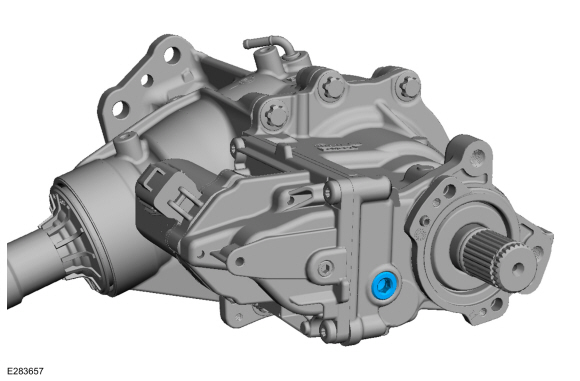

Remove the PTU drain plug.

|

-

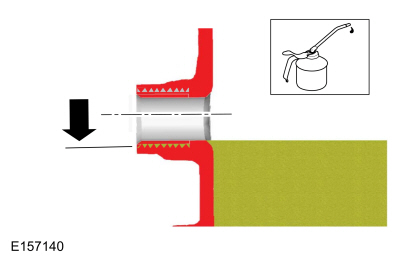

NOTE: Ensure drain plug gasket is properly seated and flush inside of drain plug groove. Drain Plug Gasket should not be visible after installation.

Install the oil drain plug with the new gasket.

Torque: 30 lb.ft (40 Nm)

|

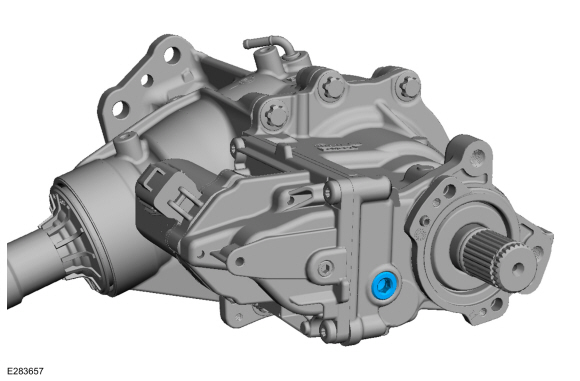

Vehicles With: Power Transfer Unit Oil-to-Coolant Cooler

-

Remove the PTU cooler to drain the fliud.

Refer to: Power Transfer Unit Cooler - Vehicles With: Power Transfer Unit Oil-to-Coolant Cooler (307-07B Power Transfer Unit - 2.0L EcoBoost (177kW/240PS) – MI4, Removal and Installation).

Filling

-

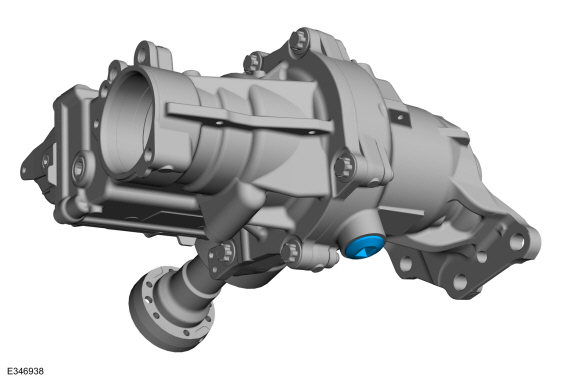

Remove the PTU fill plug.

|

-

Fill the PTU with clean fluid, level with the fill plug opening.

Refer to: Specifications (307-07B Power Transfer Unit - 2.0L EcoBoost (177kW/240PS) – MI4, Specifications).

Material: Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear Lubricant / XY-75W85-QL (WSS-M2C942-A)

|

-

Install the PTU fill plug.

Torque:

Stage 1: 133 lb.in (15 Nm)

Stage 2: 360°

|

-

Install the underbody shield.

Refer to: Engine Front Undershield (501-02 Front End Body Panels, Removal and Installation).

General Procedures - Power Transfer Unit Fluid Level Check

General Procedures - Power Transfer Unit Fluid Level Check

Materials

Name

Specification

Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear LubricantXY-75W85-QL

WSS-M2C942-A

Activation

With the vehicle in NEUTRAL, position it on a hoist...

Other information:

Lincoln Corsair 2020-2026 Service Manual: Description and Operation - Active Grille Shutter - Overview

Overview The AGS (Active Grille Shutter) system is primarily used to improve fuel economy by reducing aerodynamic drag while the vehicle in moving. It is also used to shorten engine warm-up time, which increases engine efficiency and provides faster heat delivery to the vehicle cabin...

Lincoln Corsair 2020-2026 Service Manual: Description and Operation - Handles, Locks, Latches and Entry Systems - Component Location

Item Description 1 BCM 2 Exterior Front Door Handle RH 3 RTM 4 Keyless Entry Rear Antenna 5 Exterior Front Door Handle LH 6 RKE Exterior Sounder ..

Categories

- Manuals Home

- 1st Generation Lincoln Corsair Owners Manual

- 1st Generation Lincoln Corsair Service Manual

- Fuel Quality - Gasoline

- Interior Lamps

- Head Up Display

- New on site

- Most important about car

Adjusting the Steering Wheel - Vehicles With: Power Adjustable Steering Column

WARNING: Do not adjust the steering wheel when your vehicle is moving.

Note: Make sure that you are sitting in the correct position.

Copyright © 2026 www.licorsair.com